In the rapidly evolving world of marine equipment, choosing the right injection molding solutions is critical to enhancing product performance and reducing manufacturing costs. According to the latest report from the International Marine Industry Association, the global marine equipment market has seen a staggering growth rate of 7.5% annually, further emphasizing the need for innovative manufacturing technologies. This growth has driven manufacturers to adopt advanced techniques, particularly in Marine Equipment Injection Molding, which offers superior precision and efficiency in producing high-quality parts.

Expert in marine manufacturing, Dr. Michael Carter, emphasizes that "the future of the marine industry hinges on our ability to utilize cutting-edge injection molding techniques that not only meet stringent quality standards but also contribute to sustainability." As industry demands rise, there is an increasing focus on optimizing these solutions to ensure durability and performance under harsh marine conditions. This guide will provide essential tips for selecting the best Marine Equipment Injection Molding methodologies, enabling industry professionals to make informed decisions that align with the latest technological advances and market trends.

Expert in marine manufacturing, Dr. Michael Carter, emphasizes that "the future of the marine industry hinges on our ability to utilize cutting-edge injection molding techniques that not only meet stringent quality standards but also contribute to sustainability." As industry demands rise, there is an increasing focus on optimizing these solutions to ensure durability and performance under harsh marine conditions. This guide will provide essential tips for selecting the best Marine Equipment Injection Molding methodologies, enabling industry professionals to make informed decisions that align with the latest technological advances and market trends.

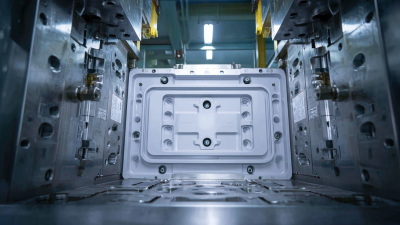

When evaluating marine equipment injection molding solutions, several key factors should be at the forefront of your decision-making process. First, consider the material compatibility and durability of the injection molded components. Marine environments demand materials that resist corrosion and can withstand extreme weather conditions, so sourcing solutions that offer high-performance resins specifically designed for marine applications is crucial. Ensure the supplier provides thorough documentation of the material properties to verify their performance under marine exposure.

Another important factor is the technical capabilities of the manufacturer. Assess whether the provider has experience specifically in marine applications, along with advanced tooling and design capabilities. An experienced manufacturer will not only deliver high-quality products but also collaborate effectively during the design phase to optimize both production efficiency and product durability. It’s also advisable to evaluate the manufacturer’s production capacity and lead times to ensure they can meet your project deadlines without compromising quality or performance.

The marine equipment manufacturing industry is set to undergo significant transformation in 2025, primarily driven by cutting-edge technologies. One of the most impactful advancements is the integration of automation and robotics in the injection molding process. This allows for precise manufacturing of complex components, reducing both time and labor costs while enhancing product quality. Automated systems not only improve efficiency but also enable manufacturers to meet the rising demand for customized marine equipment.

In addition to automation, the use of advanced materials in injection molding is revolutionizing the durability and performance of marine products. Innovations like carbon fiber composites and bio-based polymers are becoming more prevalent, offering lighter yet stronger alternatives to traditional materials. These advancements not only enhance the longevity of marine equipment but also contribute to environmental sustainability, addressing the industry's need for greener solutions. As these technologies continue to evolve, manufacturers who embrace them will be better positioned to lead the market and meet the stringent requirements of modern marine applications.

This chart illustrates the anticipated growth in the adoption of various technologies within the marine equipment manufacturing industry by 2025. It showcases the increasing trend towards advanced materials, automation, and sustainability efforts across the sector.

When budgeting for optimal injection molding solutions in the marine industry, it's crucial to analyze both short-term and long-term costs. According to a recent report by MarketsandMarkets, the global injection molding market is projected to reach $287 billion by 2025, underscoring the critical role of injection molding in producing durable marine equipment. Selecting the right materials and technologies can significantly impact the upfront investment and operational costs. For instance, high-performance polymers may come with a higher price tag but can offer improved resistance to corrosion and UV degradation, ultimately reducing replacement costs over time.

It's also vital to consider the energy consumption associated with different injection molding equipment. A study from the Plastics Industry Association indicated that modern energy-efficient molding machines can save up to 50% in energy costs compared to traditional models. By factoring in these operational savings, businesses can better align their budgets to accommodate high-quality manufacturing processes without compromising their bottom line. Investing wisely in injection molding technology not only improves product quality but can also lead to substantial long-term savings in the competitive marine industry.

| Dimension | Description | Estimated Cost ($) | Efficiency Rating (1-10) |

|---|---|---|---|

| Material Type | Nylon, Polycarbonate, PVC | 5000 - 10000 | 8 |

| Molding Technique | Standard, Insert, Blow Molding | 4000 - 12000 | 9 |

| Production Volume | Low, Medium, High | 3000 - 15000 | 7 |

| Lead Time | Quick, Standard, Custom | 2000 - 8000 | 8 |

| Post-Processing | Trimming, Coating, Assembly | 1500 - 6000 | 6 |

When embarking on marine equipment injection molding projects, selecting the right materials is crucial for ensuring both performance and longevity. According to a report by the American Composites Manufacturers Association, the use of engineering-grade thermoplastics such as Nylon, Polycarbonate, and PVC is on the rise in the marine industry. These materials offer enhanced resistance to moisture, UV exposure, and chemicals, critical characteristics for underwater applications. Selecting compounds that blend durability and lightweight properties can significantly impact product performance.

Tips: Always consider the specific environmental conditions your equipment will face. For saltwater applications, materials with superior corrosion resistance are essential. Additionally, conducting thorough compatibility tests between your chosen material and other components can preemptively address potential failures in the field.

Another key factor is the evolving regulations surrounding marine equipment materials. The International Maritime Organization (IMO) has outlined guidelines affecting material selection to ensure environmental sustainability. Keeping abreast of these changes can not only avoid compliance issues but also inspire innovation in your designs.

Tips: Regularly updating your knowledge on material advancements and regulatory standards can give you a competitive edge in the marketplace. Don’t hesitate to consult with material suppliers who can provide insights tailored to your specific injection molding needs.

The marine industry is witnessing a transformative shift in injection molding technologies, driven by innovations that enhance efficiency and sustainability. As highlighted during the recent 2024 International Plastics and Rubber Industry Exhibition in Shanghai, the focus is increasingly on advanced materials and processes that not only improve the quality of marine equipment but also minimize environmental impacts. Industry reports indicate that the global marine injection molding market is projected to reach $5.3 billion by 2025, emphasizing the need for cutting-edge solutions that cater to evolving maritime demands.

Key trends shaping the future of injection molding in marine applications include the integration of biodegradable materials, automation, and Industry 4.0 technologies. The adoption of biomaterials is particularly noteworthy; studies show that over 40% of manufacturers are considering sustainable alternatives to traditional plastics. Furthermore, advancements in automation and smart manufacturing are expected to enhance production efficiency by as much as 25%, allowing marine equipment manufacturers to reduce costs and lead times while meeting stringent quality standards. The synergy of these innovations promises to redefine the standards of marine equipment development, tailoring solutions for a rapidly changing market landscape.