Golf Cart Plastic Injection Molding has transformed the golf cart industry. Experts, like Dr. Emily Sanders, emphasize its importance: "This process reduces waste and enhances quality." The benefits are numerous, yet often overlooked.

Golf Cart Plastic Injection Molding allows for precise shapes and designs. Manufacturers can create complex parts efficiently. The ability to use different materials adds strength and durability. However, some companies still hesitate to adopt this technology. They fear high initial costs and potential production delays.

Yet, embracing this technique can lead to significant advantages. These include reduced labor costs and improved product consistency. Companies that ignore these benefits may struggle to compete in a fast-evolving market. Ultimately, understanding the full scope of Golf Cart Plastic Injection Molding is crucial for progress.

Durability plays a crucial role in golf cart plastic injection molding. High-quality plastics are essential for enduring various outdoor elements. Golf carts often face sun exposure, rain, and rough terrains. Plastic components must resist cracking and fading over time. When molded correctly, these parts maintain their integrity and appearance. This durability reduces the need for frequent replacements, saving money in the long run.

Moreover, durability ensures safety and functionality. Well-designed plastic components withstand heavy usage without compromising performance. Golf carts that rely on strong materials can handle the weight of passengers and cargo.

However, not all plastic is created equal. Some cheaper options may seem appealing initially but can lead to problems later. Investing in quality materials is vital for lasting performance. This choice impacts both the functionality and longevity of the golf cart. Consider the long-term effects when selecting materials for your golf cart components.

Plastic injection molding has become the go-to method for producing golf cart parts. This technique is particularly cost-effective for mass production. It allows manufacturers to create high volumes of parts with precision and efficiency. According to industry reports, injection molding can reduce production costs by up to 30% compared to traditional manufacturing methods.

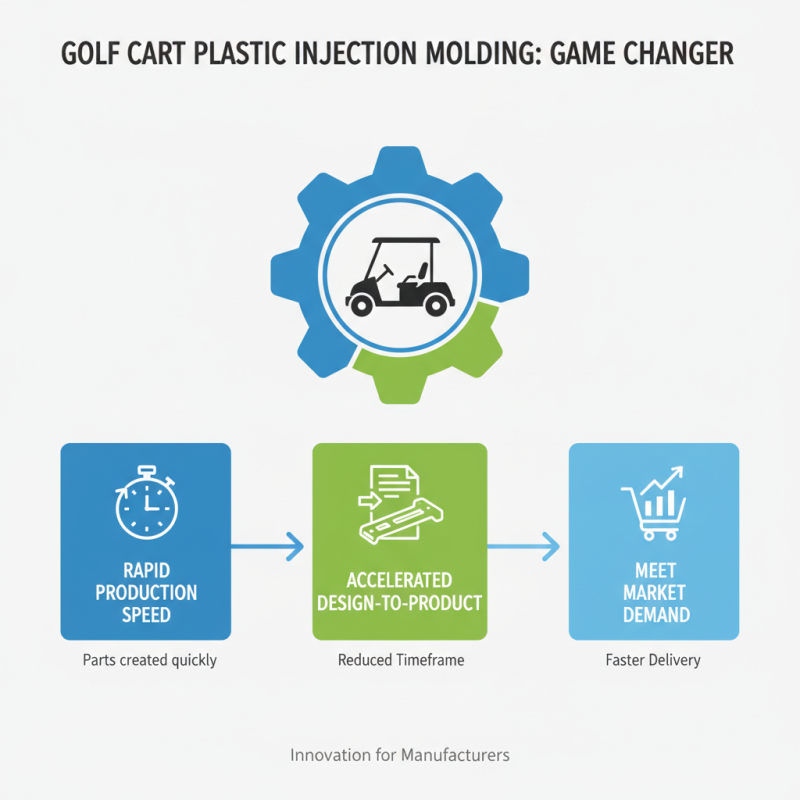

In addition to cost savings, the speed of injection molding is impressive. A single mold can produce hundreds of parts in one cycle. This speed significantly shortens the time to market. For golf cart manufacturers, quicker production times can lead to better responsiveness to customer demands. However, the initial setup costs for molds can be high, which might deter smaller companies from entering the market.

Quality control is another area to consider. While plastic injection molding yields consistent results, flaws can occur. High-temperature variations can lead to defects. Manufacturers need to invest in monitoring systems to catch these issues early. Ensuring high-quality parts remains a challenge, even with advanced technology. Balancing speed and quality is crucial for successful production.

Plastic injection molding is a game-changer for golf cart manufacturers. It allows for a wide range of customization options. Different colors, shapes, and sizes can be easily achieved. This flexibility is especially advantageous for creating unique cart designs. Customers often want something personalized, and injection molding meets that need.

Customization goes beyond just aesthetics. Features can be tailored to enhance functionality. Additional storage compartments, cup holders, or specialized seating can be molded right into the design. However, some manufacturers struggle with balancing creativity and practicality. They might want to introduce too many features, which can complicate the manufacturing process.

Moreover, it’s important to consider environmental impact. Choosing sustainable materials is vital. While injection molding offers great advantages, it requires careful material selection. The aim should be to minimize waste while maximizing design potential. Balancing cost with quality is another challenge. Sometimes, the cheapest options lead to subpar results. Reflecting on these issues can lead to better decisions in the future.

Golf cart plastic injection molding has changed the game for manufacturers. The improved production speed for golf cart components is a significant benefit. This process allows for rapid creation of parts, reducing the time from design to final product. Faster production times enable manufacturers to meet market demands quickly.

With the precision of injection molding, each component is crafted with accuracy. This leads to less material waste, unlike traditional methods. However, achieving this efficiency isn’t without challenges. Adjusting molds to minimize defects can be tricky. Finding the right balance of speed and quality requires ongoing reflection and improvement.

Incorporating advanced technologies can help streamline these processes. Automation in molding lines can enhance efficiency even further. Yet, adaptations to new systems may pose difficulties for some manufacturers. Continuous training for staff is essential. It ensures that everyone is on the same page, understanding the machinery and its advantages. Speed is crucial, but quality and sustainability must not be overlooked.

Plastic injection molding for golf carts presents notable eco-friendly advantages. This method minimizes waste during production. It creates high-quality parts with precision. Fewer materials are wasted, which is a win for sustainability. The energy-efficient process also reduces the carbon footprint. Using recyclable plastics further enhances the environmental benefits.

Tips for choosing materials matter. Opt for biodegradable options when possible. This choice promotes a greener lifecycle for the cart. Always consider the durability of the materials. They should withstand outdoor conditions without degrading quickly. This balance between strength and sustainability is key.

Additionally, the recycling potential of plastic parts is significant. When golf carts are retired, their plastic components can be reused. This aspect highlights a closed-loop system that benefits the environment. But one must reflect on why many still favor traditional materials. Change takes time. Awareness and education are essential in shifting mindsets toward sustainable practices in manufacturing golf carts.