In today's competitive market, mastering Custom Plastic Injection Molding can set your business apart. John Smith, a renowned expert in the industry, once stated, "Innovation in molding techniques can lead to remarkable cost efficiency and product quality." This highlights the importance of embracing advanced molding techniques.

Custom Plastic Injection Molding is vital for various sectors, from automotive to consumer goods. Companies can significantly enhance production by implementing the right techniques. Each technique offers unique benefits, yet finding the best fit for your needs is crucial.

Some businesses struggle with this balance. They may stick to outdated methods, missing improvement opportunities. Adopting innovative approaches can pose challenges. However, the potential rewards are substantial. Investing in the right Custom Plastic Injection Molding techniques can lead to sustainable growth and enhanced competitiveness.

Custom plastic injection molding is a transformative manufacturing process. It allows businesses to create precise plastic parts tailored to specific needs. By using this technique, companies can achieve high production rates and intricate designs. The molding process involves injecting molten plastic into a mold cavity, which then cools and solidifies.

When considering custom plastic injection molding, it's essential to understand the material options. Different plastics offer unique properties, affecting durability and flexibility. Choose the right material based on your product requirements. This decision can impact both functionality and production cost.

Tips: Collaborate with experienced engineers during the design phase. They can help optimize the mold design for better efficiency. Also, consider prototyping before committing to large-scale production. Testing prototypes can reveal flaws early on, saving time and resources later.

Attention to detail matters. Verify tolerances and dimensions to ensure product quality. Even minor mistakes can lead to significant issues in the final product. Always be open to iterating your designs. Flexibility in adapting your approach can lead to better results and innovations.

When choosing injection molding techniques, consider several key factors. The first is material compatibility. Different plastics behave uniquely during the molding process. You must select materials that align with your design needs. Testing materials before full production can save time and costs.

Another important factor is production volume. High-volume production may benefit from optimized techniques. However, if your project is smaller, simpler methods may suffice. Assess your project needs clearly. A balance between efficiency and quality is vital.

Tip: Always prototype before mass production. This step uncovers potential flaws early. Gathering feedback can be invaluable.

Additionally, evaluate the tooling cost. High-quality molds can be expensive. However, investing in quality often leads to fewer defects. This is crucial for maintaining profit margins. Never overlook the impact of skilled labor on the molding process. Their expertise can significantly affect the overall success of your project.

Tip: Consider conducting a cost-benefit analysis for different techniques. This can be an eye-opening exercise, shedding light on possible pitfalls.

| Technique | Material Compatibility | Production Speed | Cost Efficiency | Recommended Applications |

|---|---|---|---|---|

| Standard Injection Molding | ABS, PP, PS | High | Moderate | Consumer products, automotive parts |

| Gas-Assisted Injection Molding | PA, ABS | Moderate | High | Hollow parts, large items |

| Multi-Cavity Injection Molding | PP, PVC | Very High | Very High | Mass production |

| Two-Shot Injection Molding | PC, TPU | High | Moderate | Complex parts, overmolding |

| Insert Molding | Various | Moderate | Moderate | Electrical components, connectors |

| Compression Molding | Rubber, silicone | Low | Low | Seals, gaskets |

| Rotational Molding | PE, PVC | Moderate | High | Large hollow objects |

| 3D Printing Injection Molding | PLA, ABS | Low | Moderate | Prototyping, bespoke designs |

| High-Pressure Injection Molding | PC, Nylon | Very High | High | Tough parts, high-performance applications |

| Biodegradable Injection Molding | PLA, PHA | Moderate | High | Eco-friendly products, packaging |

Custom plastic injection molding is a pivotal technology for modern businesses. It allows companies to create precise parts quickly. This technique uses thermoplastics to achieve high-quality results. In fact, reports indicate that the global market for injection molding is projected to reach $345 billion by 2025. This growth reflects its importance across many industries.

Choosing the right molding technique can significantly affect production efficiency. For instance, gas-assisted injection molding offers unique advantages. It reduces the weight of the final product while maintaining strength. However, it might require higher initial investments. Similarly, multi-component injection molding can produce complex parts in one cycle. Adopting such methods can streamline operations, but they come with a steeper learning curve. Companies need to weigh the benefits against their own capabilities and resources.

Quality control remains a significant challenge in this field. Molding defects can lead to costly recalls and wastage. Data indicates that approximately 30% of molded parts fail quality tests at first. This highlights the necessity for robust testing procedures. Investing in advanced technologies, like real-time monitoring, may help mitigate these risks. Businesses must find a balance between innovation and practicality to thrive in today's competitive environment.

Injection molding is a key technique for many businesses. Various methods exist, each with distinct benefits. Choosing the right technique can significantly enhance production efficiency.

One popular technique is gas-assisted injection molding. It reduces material use, leading to cost savings. This method also allows for lighter parts, which can be crucial for many applications. However, it requires precise control. Small errors can result in defects.

Tip: Always evaluate your design for material efficiency before starting the process. This small step can lead to better outcomes.

Another method, multi-shot injection molding, enables the creation of complex parts in one go. This reduces assembly time and costs. However, the setup can be complicated. It may not be suitable for simple designs.

Tip: Consider the complexity of your design thoroughly. Sometimes, simpler methods might suit your needs better than advanced techniques.

Using techniques like these can streamline your production process. They offer flexibility and can meet various needs. Be mindful of the trade-offs involved in each technique to ensure the best fit for your project requirements.

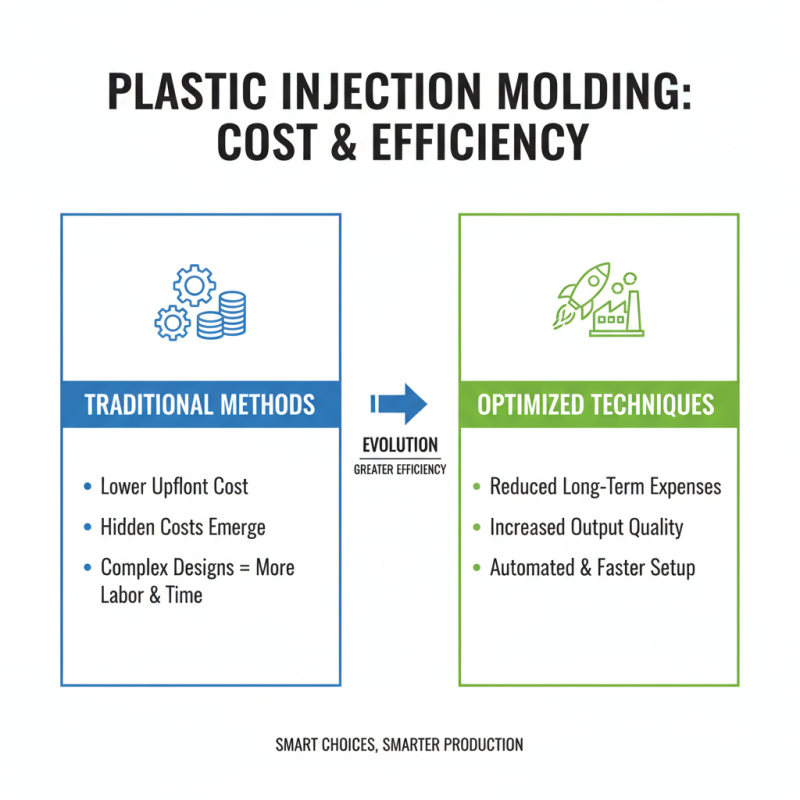

When considering plastic injection molding, cost and efficiency are pivotal. Different techniques can significantly impact production expenses and output quality. Traditional methods may appear cheaper upfront, but hidden costs often emerge. For example, complex designs may require additional labor and longer setup times.

On the other hand, advanced techniques like multi-cavity molding can increase efficiency. This process allows for multiple parts to be created simultaneously, saving time. However, the initial investment in such technology can be daunting. Companies must weigh the potential for faster turnaround against the upfront costs.

Additionally, material choice plays a critical role. Using high-quality plastics may improve durability but could lead to higher production costs. The key lies in balancing these factors to achieve both cost-effectiveness and quality in your production. Exploring various techniques will reveal strengths and weaknesses that may not be immediately apparent.