In the competitive landscape of marine equipment manufacturing, optimizing production processes is crucial for enhancing performance and driving innovation. One of the most effective ways to achieve this is through Marine Equipment Injection Molding. This advanced manufacturing technique not only increases efficiency but also improves the quality and durability of components used in various marine applications. By adopting best practices in this specialized molding process, manufacturers can significantly reduce waste and enhance the overall performance of their products.

This article explores the 10 best practices for Marine Equipment Injection Molding, providing insights that can help industry players refine their production methods. From material selection to machine maintenance, each practice contributes to minimizing defects, maximizing output, and ultimately, delivering superior marine equipment. As we delve into these practices, it becomes clear that a strategic approach to injection molding is essential for staying ahead in a rapidly evolving industry, while also meeting the rigorous demands of marine environments.

When it comes to marine equipment injection molding, material selection plays a pivotal role in enhancing performance and efficiency. The unique challenges posed by marine environments, such as exposure to moisture, saltwater, and extreme temperatures, necessitate careful consideration of materials that can withstand these conditions. High-density polyethylene (HDPE), for instance, is often preferred for its excellent corrosion resistance and durability, making it suitable for various marine applications.

**Tip:** Always evaluate the mechanical properties of potential materials under the specific conditions of use. This includes testing for UV resistance, impact strength, and thermal stability to ensure long-lasting performance.

Additionally, the choice of additives can further optimize material properties. UV stabilizers and anti-fouling agents are important considerations that can enhance the longevity and functionality of marine components. Using materials with built-in colorants can also benefit aesthetic appeal while ensuring visibility and safety on the water.

**Tip:** Collaborate with suppliers who specialize in marine-grade materials. Their expertise can guide you in selecting the right combinations of polymers and additives that align with your product requirements and performance goals.

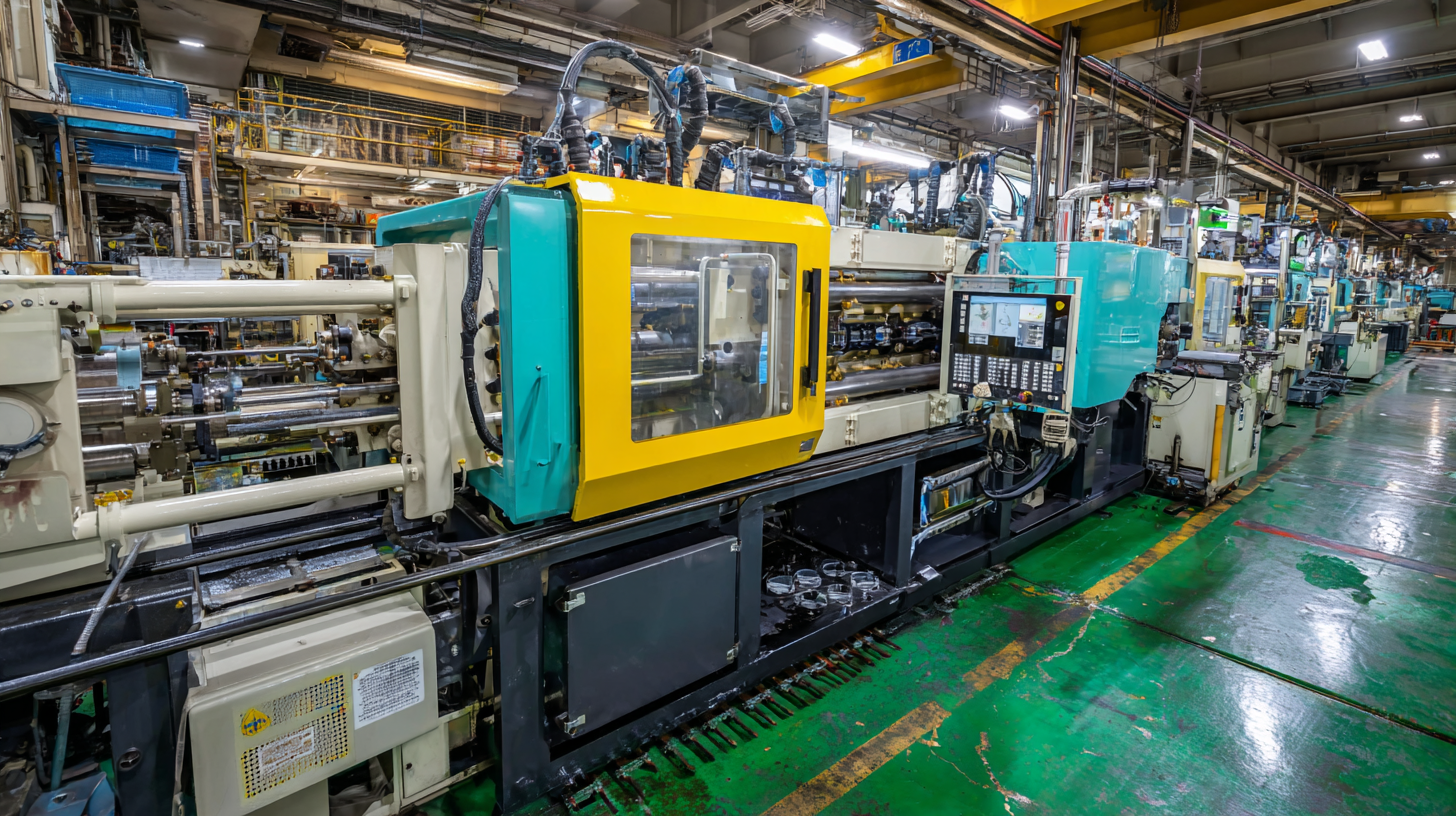

Temperature control is a critical factor in the injection molding of marine equipment, significantly influencing the quality and performance of the final products. In a study conducted by the Society of Plastics Engineers, it was reported that maintaining optimal melt temperature within a range of 180°C to 220°C can reduce defects such as warping and shrinkage by up to 30%. Proper temperature management allows for uniform material flow and consistent filling of molds, which is essential when dealing with the complex geometries often found in marine applications. Furthermore, precision in temperature control leads to improved surface finish, which is vital for both aesthetic appeal and performance in demanding marine environments.

Additionally, the cooling phase of the injection molding process is just as important. According to a report from the American Society of Mechanical Engineers, effective cooling can decrease cycle times by approximately 15-25%, thereby enhancing productivity without compromising the quality. This is particularly relevant in the marine industry, where the functionality and durability of components are non-negotiable.

By implementing advanced temperature control technologies, manufacturers can ensure that marine equipment meets stringent performance standards while optimizing production efficiency. In essence, the impact of temperature management transcends mere process efficiency, directly correlating with the reliability and longevity of marine products.

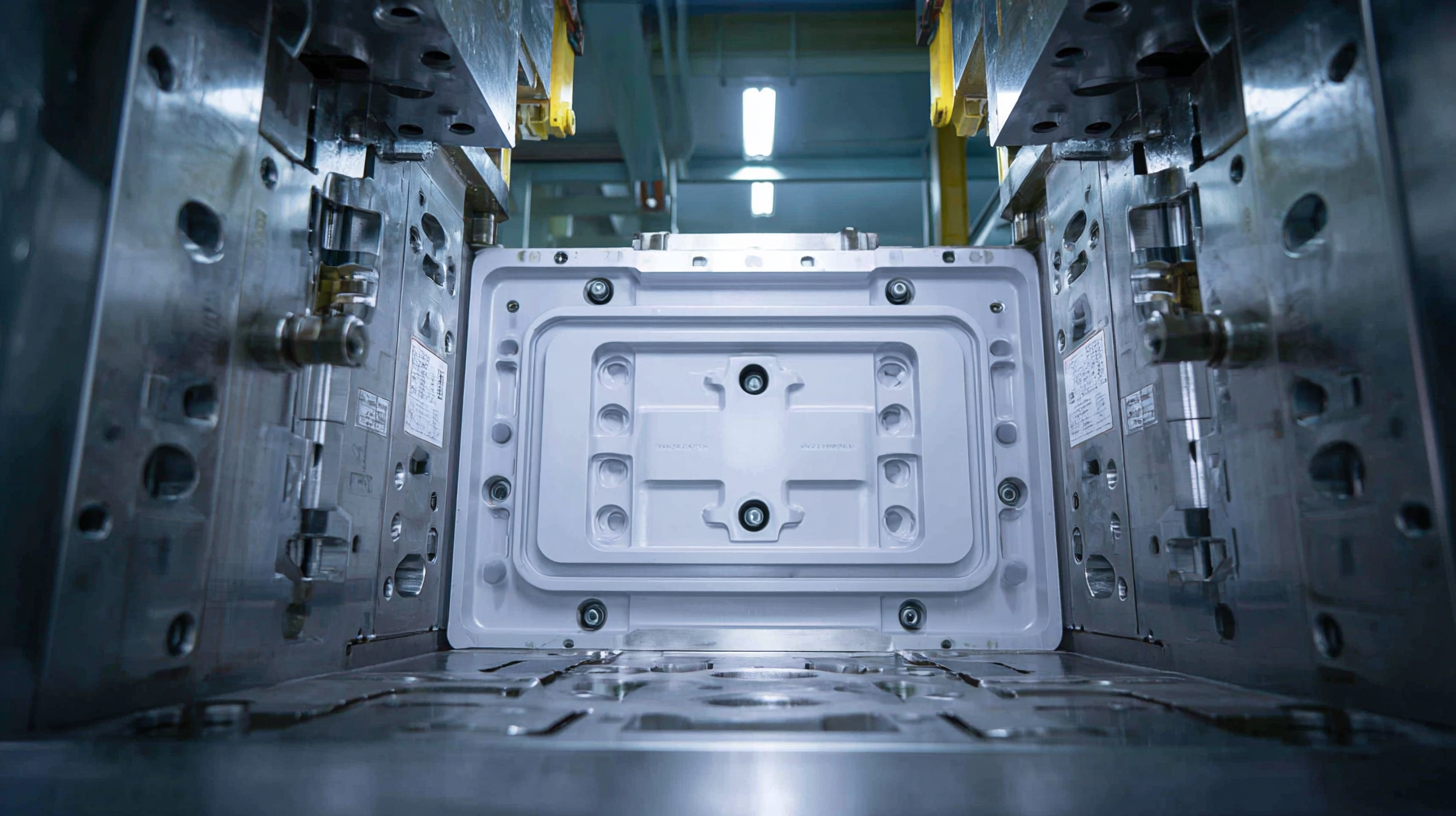

Innovative mold design techniques play a crucial role in enhancing efficiency in marine injection molding. One of the key approaches is the use of advanced simulation software during the mold design phase. By employing tools that predict flow patterns and thermal behavior, manufacturers can optimize cavity layout and cooling channels before the mold is even built. This not only reduces material waste but also shortens cycle times, improving overall throughput.

Additionally, incorporating modular design into molds allows for quick adjustments and replacements of specific components without the need for complete overhauls. This adaptability is particularly beneficial in marine applications, where varying part sizes and complexities are common. The integration of features such as self-lubricating bushings or advanced venting systems can further enhance the performance and longevity of the molds, resulting in higher-quality outputs and reduced maintenance downtime. Overall, innovative mold design techniques are vital for achieving superior performance in marine equipment injection molding.

When evaluating injection molding performance in marine equipment production, several key metrics come into play. First and foremost, cycle time is critical; it determines the speed at which molds are filled, cooled, and ejected. A shorter cycle time often translates to increased productivity. Additionally, monitoring the consistency of shot weight helps ensure that each part meets stringent quality standards, which is crucial for marine applications where precision is paramount.

Tips: Regularly calibrating your injection molding machines can significantly reduce variability in shot weight and cycle times. This calibration should be part of a routine maintenance schedule to sustain optimal performance.

Another important metric is the defect rate. Tracking defects such as surface imperfections or dimensional inaccuracies is essential for quality assurance. Minimizing the defect rate not only enhances product reliability but also reduces waste, ultimately improving cost-efficiency in the manufacturing process.

Tips: Implementing real-time monitoring systems can help identify issues during production, allowing for immediate corrective actions to maintain low defect rates and ensure high-quality outputs.

Sustainability has become a focal point in marine equipment manufacturing, particularly through advanced injection molding techniques. Recent studies indicate that the marine sector is responsible for approximately 3% of global greenhouse gas emissions, pushing manufacturers to adopt greener practices. By leveraging advanced injection molding technologies, companies can significantly reduce waste and energy consumption. For instance, innovative thermoplastics not only enhance durability but also decrease production waste by up to 30%, aligning with the industry's push toward a circular economy.

Moreover, adopting sustainable materials in injection molding can further support ecological goals. According to a report from the Marine Industry Association, using biodegradable or recycled materials can cut emissions by more than 50% compared to traditional plastics. This shift not only minimizes environmental impact but also meets the increasing consumer demand for eco-friendly products. As marine equipment manufacturers integrate these sustainable practices into their production processes, they set a standard for reducing the industry's carbon footprint while improving overall equipment performance and reliability.

| Best Practice | Description | Sustainability Impact | Performance Improvement |

|---|---|---|---|

| Material Selection | Choosing biodegradable or recycled materials for production. | Reduced environmental footprint. | Enhanced durability and longevity. |

| Energy Efficiency | Utilizing energy-efficient molding machines to cut energy consumption. | Lower energy costs and carbon emissions. | Faster production cycles. |

| Waste Reduction | Implementing closed-loop recycling systems for scrap materials. | Minimized landfill waste. | Cost savings on raw materials. |

| Process Optimization | Improving mold designs and injection parameters for accuracy. | Increased efficiency and less wasted material. | Higher quality end products. |

| Supply Chain Management | Collaborating with suppliers to source sustainable materials. | Strengthened sustainability metrics. | Improved material quality. |

| Advanced Technologies | Incorporating 3D printing and automation for mold production. | Reduced resource consumption. | Improved precision and reduced cycle times. |

| Training and Education | Providing ongoing training on sustainable practices for workers. | Enhanced overall operational sustainability. | Higher employee engagement and productivity. |

| Lifecycle Assessment | Conducting assessments to evaluate the environmental impact of products. | Informed decision-making for sustainability improvements. | Increased market competitiveness. |

| Regulatory Compliance | Adhering to environmental regulations in manufacturing processes. | Avoided fines and penalties for non-compliance. | Enhanced brand reputation. |

| Innovation and R&D | Investing in research to develop new sustainable materials and technologies. | Pioneering new sustainability practices. | Driving future growth and market leadership. |