In today's competitive manufacturing landscape, choosing the right partner is crucial. Injection molding companies stand out for their efficiency and precision. They offer a range of services that meet various production requirements. This flexibility can greatly benefit businesses looking to streamline their manufacturing processes.

Injection molding is a powerful technology that allows for high-volume production. These companies excel in creating complex shapes and detailed designs. Their ability to work with different materials adds to their appeal. Yet, not all companies provide the same quality and service. Some may lack the necessary expertise or advanced technology.

When selecting injection molding companies, companies should consider various factors. Cost, quality, and turnaround time matter greatly. It is also essential to evaluate their customer support and communication. A thorough analysis can lead to a fruitful partnership that enhances your production capabilities.

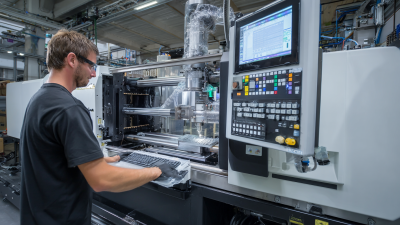

Injection molding is a widely used manufacturing process. It involves injecting molten material into a mold. This method allows for the production of complex shapes with high precision. One key advantage of injection molding is its efficiency. Once the mold is created, the production rate can be extremely high. This is beneficial for industries needing large quantities of parts.

When choosing injection molding companies, consider their experience and capabilities. Not all companies offer the same quality or speed. Some may struggle with tight deadlines or intricate designs. It’s crucial to assess their previous work and customer feedback. A reliable partner can greatly influence your project's success.

Tips: Always request samples before committing. This ensures the quality meets your standards. Collaborating closely during the design phase can save time and reduce errors. Remember, effective communication is essential. Discuss any potential challenges openly. Engaging with the manufacturer early on can lead to better outcomes.

Injection molding companies offer significant advantages for manufacturing needs. One key benefit is efficiency. They can produce thousands of identical parts rapidly. Reports state that injection molding can increase production speed by up to 30% compared to traditional methods. This speed is crucial when time-to-market is essential.

Cost savings is another critical factor. Companies that utilize injection molding often see reduced material waste. Industry analysis estimates that this process can minimize scrap rates by around 10-20%. This efficiency not only cuts costs but can also lead to better environmental practices. The ability to create complex designs at lower costs is enticing for many businesses.

Collaboration with injection molders allows for innovation. Many companies provide engineering support to refine product design. This partnership can foster improvements that enhance performance and reduce production time. However, it is essential to choose a partner wisely. Not all firms have the same track record or quality standards. Companies should carefully assess technical capabilities and past performance before committing.

When selecting an injection molding service, several factors demand attention. Quality assurance is critical. Many companies utilize ISO certification as a benchmark. This ensures that they adhere to international quality standards. According to industry reports, over 70% of leading manufacturers prioritize quality checks. This data highlights the importance of strict quality control in production.

Cost-effectiveness is another vital consideration. While low quotes may be tempting, hidden costs can arise. Reports indicate that nearly 30% of projects exceed budgets due to unforeseen expenses. Therefore, ensure clarity in pricing structures. Transparency fosters trust and avoids pitfalls later in the process.

Lastly, the choice of materials can greatly influence the final product. Not all injection molding companies offer a wide range of materials. Some focus on specific types, which may limit your options. Engaging with suppliers who have extensive material knowledge is beneficial. A lack of insight in material selection could lead to performance issues in the finished product. Reflecting on these elements can guide you in making an informed choice.

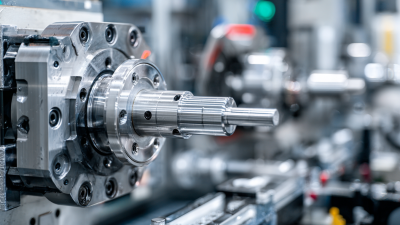

Injection molding is a versatile manufacturing process. Many industries benefit from its efficiency and precision. The automotive sector heavily relies on injection molding for producing components like dashboards and engine parts. These parts require strict specifications, and this technology meets those demands.

Consumer goods also utilize this process. Items such as plastic containers, toys, and household appliances are created through injection molding. It allows for intricate designs and rapid production cycles. However, it’s important to note the environmental concerns. Many plastic products can become waste, highlighting the need for sustainable practices.

Medical devices represent another key application. Injection molding produces components for syringes, valves, and other essential tools. These products require high-quality standards. Production errors can have significant consequences in healthcare. This underscores the need for precision and a thoughtful approach in the design phase. Hence, as businesses rush to adopt this technology, they must also consider the long-term impacts.

The injection molding industry is evolving rapidly. Innovations in technology are reshaping how products are made. Automation and smart technology are now integral to this process. Factories are becoming more efficient, yet this comes with challenges. Companies must adapt to keep up with these changes.

Sustainability is a significant trend in injection molding. Many manufacturers are exploring eco-friendly materials and processes. This shift may come with higher costs initially. Companies need to balance sustainability with profitability. The focus on reducing waste and energy consumption can lead to long-term benefits.

However, these advancements may not suit every company. Smaller manufacturers might struggle to adopt new technologies. They may need time to invest in equipment and training. It's essential to take a measured approach. Rushing into the latest trends could result in financial strain. Therefore, a thoughtful plan is critical for successful adoption in the manufacturing landscape.