Choosing the right custom plastic injection molding process is a critical decision for any manufacturing project, as it significantly impacts the product's quality, cost, and overall success. This technique allows for the mass production of precise and complex parts by injecting molten plastic into custom-designed molds. However, with various options available, selecting the appropriate custom plastic injection molding method can be daunting for businesses. This overview delves into the essential factors to consider, helping you navigate through the complexities associated with this manufacturing process.

Understanding your project's unique requirements is the first step toward making an informed choice. Factors such as material selection, design specifications, production volume, and budget constraints all play a crucial role in determining the best fit for your needs. Additionally, recognizing the intricacies of the injection molding cycle, from the initial design phase to post-production considerations, will empower you to make strategic decisions that align with your project's goals. By evaluating these elements thoroughly, you will be better equipped to choose the right custom plastic injection molding process, ensuring efficiency and excellence in production.

Custom plastic injection molding is a pivotal process in manufacturing, enabling the production of intricate plastic components with high precision. Understanding the fundamentals of this technology can significantly impact the success of your project.

According to industry reports, the global plastic injection molding market is expected to reach $340 billion by 2025, driven by the increasing demand for lightweight materials across various sectors, including automotive and consumer goods.

The process begins with melting plastic granules, which are then injected into a mold under high pressure, allowing for complex shapes and designs. Key factors to consider include the type of plastic material, the design of the mold, and production volume. Notably, the choice of material can influence not just the product’s durability but also its cost-effectiveness. For projects requiring high performance, engineers often weigh between thermoplastics and thermosetting plastics based on their specific properties and application suitability.

Tips: When selecting a custom injection molding partner, ensure they have advanced technologies and a strong track record in your industry. Additionally, consider conducting a thorough design review to minimize costs related to redesigns later on. Engage early with your injection molder to address potential design challenges, as this proactive approach can lead to more efficient production and superior product quality.

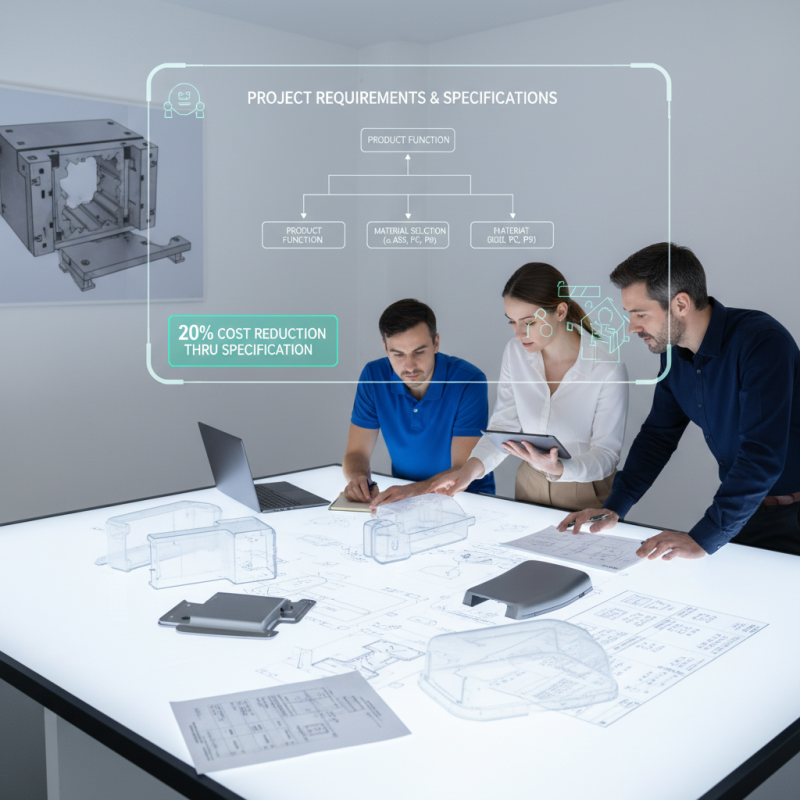

When embarking on a custom plastic injection molding project, the first step is identifying your project requirements and specifications. This involves understanding the intended function of your product, the materials required, and the projected manufacturing volume. According to a report by the Society of Plastic Engineers, proper specification can reduce production costs by as much as 20% while improving overall material efficiency. It's crucial to establish clear parameters regarding dimensions, tolerances, and performance characteristics to ensure the end product meets both functional and aesthetic standards.

Another important aspect to consider is the technological capabilities of the injection molding process. Various methods, such as multi-cavity and family mold designs, can significantly impact the efficiency and cost of production. The Plastics Industry Association notes that utilizing advanced molding techniques can enhance production rates by approximately 30%, making it vital to align your project needs with the capabilities of the selected molding process. Furthermore, conducting a thorough evaluation of potential material choices, such as thermoplastics or thermosets, can further dictate the durability and applicability of the final product, aligning it with the intended market demand.

When evaluating material options for injection molding, it is crucial to consider the specific requirements of your project. Different plastics offer varying benefits in terms of strength, flexibility, temperature resistance, and cost. For example, thermoplastics, like ABS and polycarbonate, are popular for their ease of processing and wide range of applications, while thermosetting plastics, such as epoxies, provide enhanced durability and heat resistance.

**Tips:** Always assess the mechanical properties needed for your final product. If your application demands high impact resistance and toughness, look into materials designed for those characteristics. Additionally, consider the environment in which the product will be used. Will it face extreme temperatures or chemical exposure? Choosing a material with the right resistance to these factors is essential for longevity and performance.

Another consideration is the end-use of the product. If your injection-molded parts require compliance with industry regulations, it's imperative to select materials that meet these standards. Biodegradable options are increasingly available, offering a sustainable pathway for projects focused on environmental impact.

**Tips:** Conduct a lifecycle assessment of your material choices to understand their impact from production to disposal. Engaging with material suppliers early in the design process can provide valuable insights into which options align best with your project goals while optimizing cost and performance.

| Material Type | Applications | Mechanical Properties | Cost Range (per kg) | Lead Time |

|---|---|---|---|---|

| ABS | Consumer Products, Automotive Parts | Good impact resistance, Moderate strength | $2.50 - $4.00 | 2 - 4 weeks |

| Polycarbonate (PC) | Safety Glasses, Electronic Housings | High impact strength, Good thermal stability | $3.00 - $5.00 | 3 - 5 weeks |

| Nylon (PA) | Mechanical Parts, Textiles | Excellent wear resistance, High tensile strength | $4.00 - $6.00 | 3 - 6 weeks |

| Polyethylene (PE) | Food Containers, Bottles | Good chemical resistance, Low density | $1.50 - $3.00 | 2 - 4 weeks |

| Polypropylene (PP) | Packaging, Automotive Industry | Good fatigue resistance, Low moisture absorption | $1.80 - $3.50 | 2 - 4 weeks |

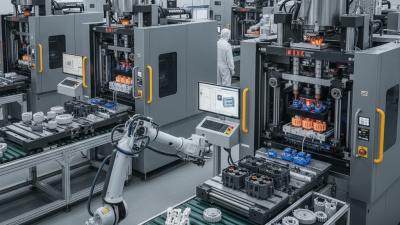

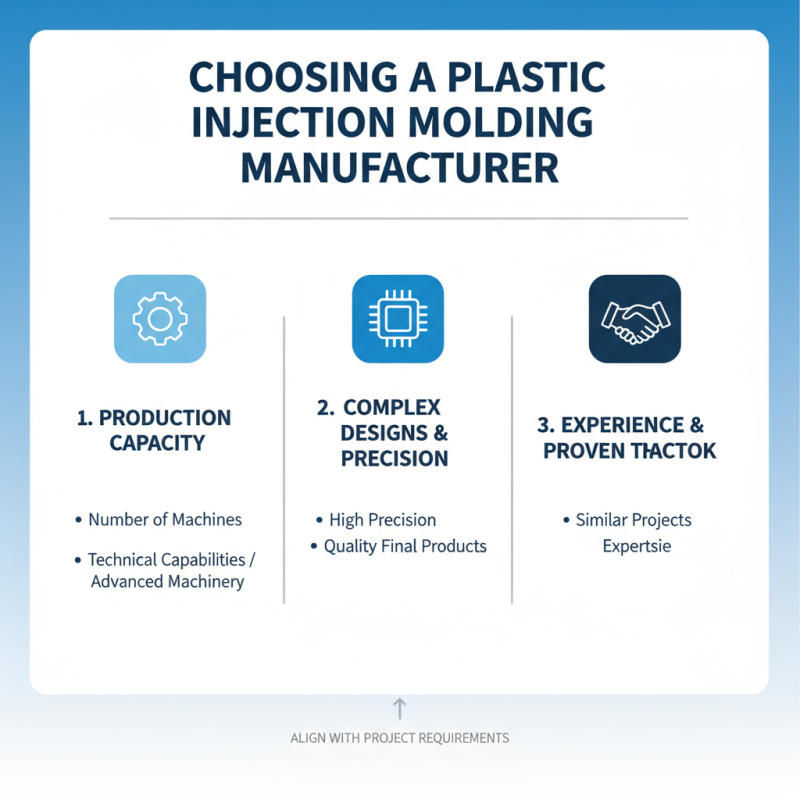

When selecting a manufacturer for custom plastic injection molding, it's crucial to assess their capabilities to ensure they align with your project requirements. Begin by evaluating their production capacity, which includes the number of machines they operate and their technical capabilities. A manufacturer with advanced machinery is more likely to meet complex designs, ensuring high precision and quality in the final products. Also, consider their experience with similar projects; manufacturers with a proven track record can provide reassurance that they have the necessary expertise to handle your specific needs.

Additionally, communication and support services offered by the manufacturer play a significant role in the selection process. A responsive manufacturer who prioritizes collaboration can facilitate smoother project execution. Look for a company that offers design assistance and rapid prototyping to help streamline your project timeline. Furthermore, inquire about their quality control processes to ensure they maintain high standards throughout production. A manufacturer committed to continuous improvement and customer satisfaction can make a significant difference in the overall success of your custom plastic injection molding project.

When selecting the right custom plastic injection molding for your project, assessing cost considerations and production timelines is crucial. According to a report by Grand View Research, the global injection molding market is expected to reach $413.72 billion by 2026, reflecting the importance of understanding these factors. The costs associated with injection molding can vary significantly based on materials, design complexity, and production volume. For instance, the cost per part typically decreases as the volume increases, making it essential to forecast the required quantities accurately. An initial investment in high-quality molds can be substantial, often ranging from $5,000 to $100,000; however, this cost should be weighed against the potential savings in mass production.

Additionally, production timelines are an integral part of the planning process. Typically, the entire custom injection molding process, from design to finished product, can take anywhere from a few weeks to several months. A recent study highlighted that effective project management can reduce lead times by approximately 30%. Key factors that influence these timelines include the complexity of the part design, the number of modifications required, and the efficiency of supplier communication. By carefully analyzing these elements, businesses can minimize costs while ensuring timely delivery, aligning with their overall project goals.