The automotive industry is witnessing rapid growth, with a projected value exceeding $2 trillion by 2025. This surge emphasizes the critical role of Automotive Plastic Injection Molding Companies in manufacturing components that enhance performance and reduce weight. Injection molding is key in producing complex parts with precision, making it a preferred choice for automakers aiming to improve efficiency.

Choosing the right molding company is crucial. Various reports indicate that over 20% of production issues arise from poor quality materials. An effective partnership can lead to innovations that drive cost savings and sustainability. However, navigating the sea of suppliers can be daunting. Not every company meets industry-specific standards, which can impact your production.

It is essential to evaluate the capabilities and track records of potential partners. A holistic approach can mitigate potential risks. Finding expertise in specific materials and processes can be as important as understanding the manufacturing timeline. Ultimately, careful selection is vital in maintaining competitiveness in a demanding market.

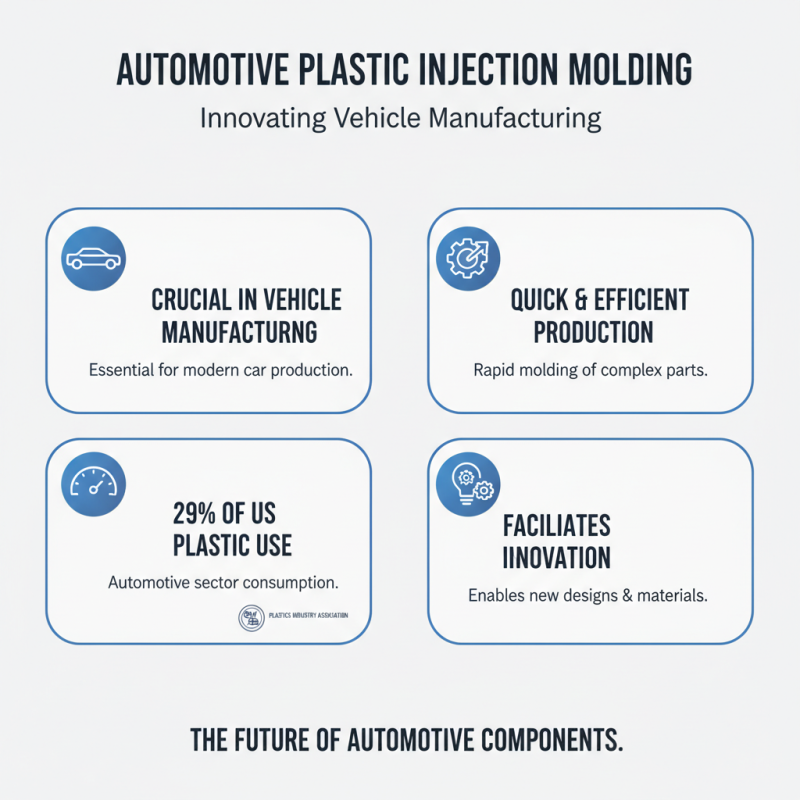

Automotive plastic injection molding is crucial in vehicle manufacturing. This process allows for the production of complex parts quickly and efficiently. According to a report by the Plastic Industry Association, the automotive sector accounts for approximately 29% of all plastic usage in the United States. As manufacturers seek to innovate, understanding the basics is essential.

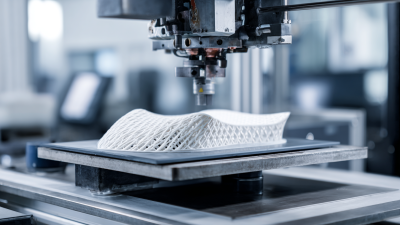

The injection molding process begins with heated plastic pellets. These pellets are melted and injected into molds, forming various automotive components. The finished parts can range from dashboards to exterior panels. This method is both cost-effective and versatile. However, quality control must be stringent to avoid defects.

**Tip:** Always evaluate a company's production capabilities. Look for modern machinery and experienced personnel. They can impact the precision and quality of your parts.

In addition, be aware of the material selection. The type of plastic used can affect durability and performance. Different plastics offer various benefits, from weight reduction to enhanced aesthetics. Yet, choosing the wrong material can lead to unexpected failures in performance or longevity.

**Tip:** Discuss with potential partners about their materials knowledge. A solid understanding will reflect their commitment to quality.

When selecting automotive plastic injection molding companies, several key factors come into play. One critical aspect is the company's experience in the automotive industry. Research shows that companies with over ten years of expertise have a 30% lower defect rate. This experience often translates to better quality control practices.

Another factor to consider is the technology used in their manufacturing processes. Companies utilizing advanced techniques, such as multi-cavity molds or automation, can produce parts more efficiently and with greater precision. A recent industry report indicated that such companies see a 25% increase in production output. However, relying solely on technology can be risky if staff training is lacking. It's essential to ensure that skilled labor is present to operate and maintain these advanced systems effectively.

Additionally, assessing a company’s customer service is vital. Prompt communication and problem resolution can make a significant difference in the production timeline. A survey indicated that 65% of customers prefer companies that prioritize clear communication. Poor customer service can lead to delays and increased costs. Make sure to gauge feedback from previous clients. This will provide insight into their reliability and responsiveness. Balancing these factors can lead to a more informed decision for your specific automotive needs.

When evaluating automotive plastic injection molding companies, experience matters. A company with years in the industry likely has faced various challenges and developed effective solutions. Look for firms that handle complex projects. Their track record can provide insights into their capabilities. Consider their project portfolio. Are their past works relevant to your needs? This can indicate how well they might serve your requirements.

Expertise also plays a crucial role in provider selection. Check if the company employs skilled engineers and technicians. Their knowledge can significantly impact the quality of the final product. Ask about the types of materials they specialize in. Different materials require different processing techniques. Specialized knowledge in various plastics can be a huge advantage. It can also be a red flag if a company focuses on only one material or process without versatility.

Not all companies are perfect. Some may have experience but lack in customer service. Response times and communication can suffer in busy firms. This is an important factor to consider. You want a provider who listens and adapts. Look for reviews that highlight these aspects. A company's ability to reflect on its weaknesses and improve can be more important than having an impeccable record.

When evaluating automotive plastic injection molding companies, quality standards play a crucial role. A well-established company should demonstrate compliance with industry-recognized certifications. These certifications often indicate a commitment to producing reliable products. Without proper certifications, it can be challenging to gauge the quality of their work.

In the molding process, attention to detail is essential. Companies must adhere to stringent guidelines to minimize defects. Even slight errors in manufacturing can result in costly recalls. Look for companies that maintain rigorous quality control measures throughout production. Product testing is also vital. Understanding the testing procedures helps identify potential failures before they reach the market.

However, not all companies maintain consistent quality. Some might have impressive certifications but fail in practical applications. Monitoring their production cycles can reveal discrepancies in quality. Engage with past clients to gain insights into their experiences. This feedback can illuminate potential issues or successes you might not see on the surface. In choosing the right company, balancing certifications with real-world performance is crucial.

When selecting automotive plastic injection molding companies, cost is a key factor. Some firms may offer low prices, but don’t rush to choose them. Remember that lower costs might mean compromised quality. Investigate if their materials meet industry standards. Consider potential extra expenses, like shipping or tooling. A cheap quote can quickly become costly down the line.

Lead times are equally important. Some companies promise fast turnaround, but not all can deliver. Ask for specific timelines and check for any past delays. Delays can impact your production schedule. Look for customer reviews that mention reliability. Honest feedback from previous clients can provide valuable insight.

Customer reviews serve as a window into a company's strengths and weaknesses. Focus on feedback related to quality, service, and support. Some reviews may be overly positive, while others highlight serious issues. Balance the information. A pattern of complaints may mean trouble. A few negative reviews can be normal. However, if poor reviews dominate, proceed with caution. Attention to details in feedback will guide your choice effectively.

| Company Type | Average Cost per Part | Lead Time (Days) | Customer Rating (Out of 5) | Additional Services |

|---|---|---|---|---|

| Domestic Manufacturer | $1.50 | 15 | 4.7 | Design Assistance, Tooling |

| Overseas Manufacturer | $0.80 | 30 | 4.2 | Volume Discounts |

| Local Prototyping Service | $2.00 | 10 | 4.9 | Fast Prototyping |

| Specialized Niche Provider | $2.50 | 25 | 4.5 | Custom Solutions |

| Large Volume Manufacturer | $1.20 | 20 | 4.8 | Logistics Support |