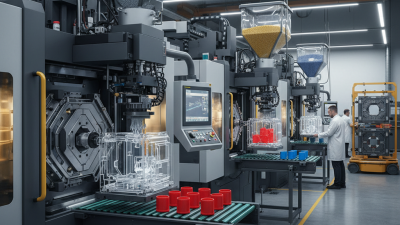

The marine industry has long relied on the durability and performance of materials that can withstand harsh environmental conditions. As the demand for high-performance components grows, the selection of appropriate materials becomes ever more critical. Among various options, "Injection Molding Plastic for Marine Application" has gained prominence due to its versatility and ability to meet specific requirements such as corrosion resistance, UV stability, and high strength-to-weight ratios. According to a recent industry report by Research and Markets, the global marine plastics market is expected to reach $XX billion by 2025, further emphasizing the importance of employing advanced materials.

When considering Injection Molding Plastic for Marine Applications, stakeholders must evaluate factors such as material properties, processing techniques, and long-term performance under harsh conditions. A study published in the Journal of Marine Science and Engineering highlights that polymers used in marine environments must not only be sturdy but also have low water absorption rates to maintain their integrity over time. Additionally, the lightweight nature of injection-molded plastics contributes to fuel efficiency and overall performance in various marine applications, from hull components to interior fittings.

In conclusion, making informed choices about Injection Molding Plastic for Marine Applications can significantly impact the longevity and reliability of marine products. With ongoing innovations in material science and engineering, there is a robust opportunity to explore new formulations and manufacturing techniques that align with the evolving needs of the marine sector. Stakeholders should utilize industry reports and expert insights to navigate this complex landscape effectively.

Marine environments present unique challenges that require careful consideration when selecting injection molding plastics. Factors such as exposure to saltwater, UV radiation, and extreme temperatures can significantly impact the performance and durability of materials used. Therefore, it is essential to understand these demands to ensure longevity and reliability of components in marine applications.

One of the primary concerns in marine applications is the potential for corrosion and degradation due to constant exposure to harsh conditions. Plastics used in this context must possess resistance to corrosion as well as the ability to withstand the damaging effects of UV rays, which can cause fading and brittleness over time. Additionally, selecting materials with low moisture absorption properties is crucial to prevent warping and maintain dimensional stability. Understanding the environmental conditions specific to the intended application, such as freshwater versus saltwater use, can greatly inform the choice of material and its formulation.

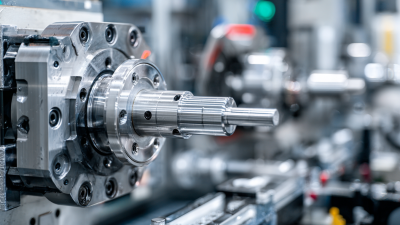

Moreover, mechanical properties are critically important in marine applications. The chosen plastic must endure high impact and stress, particularly in components subject to dynamic loads. Flexural strength, tensile strength, and fatigue resistance are vital characteristics to assess when evaluating different types of plastics for boats, docks, and other marine structures. Balancing these mechanical needs with the chemical resilience required for marine environments is key to ensuring that the chosen injection molding plastic can perform effectively over time.

When selecting plastics for marine applications, certain key properties are essential to ensure durability and functionality in harsh environments. First and foremost, resistance to corrosion and degradation from saltwater is critical. Marine plastics must withstand constant exposure to moisture, UV rays, and fluctuating temperatures without compromising their structural integrity. High-performance materials like polypropylene and polycarbonate are often favored for their robust resistance to these elements.

Another vital property is impact resistance. Marine environments can be unpredictable, with potential for collisions and stress from waves. Plastics used in this context should possess high toughness to avoid cracking or breaking under sudden impact. Additionally, buoyancy is an important consideration—some applications may require materials that can float or aid in flotation, necessitating the use of lightweight plastics.

Finally, the capability to maintain mechanical properties across a range of temperatures ensures reliability, from the heat of sunlight to the chill of deep waters. By focusing on these critical properties, manufacturers can make informed choices when selecting injection molding plastics for marine applications.

When selecting injection molding plastics for marine applications, several critical factors must be considered to ensure durability and performance in challenging environments. One of the primary considerations is the material's resistance to UV radiation and saltwater exposure. Marine conditions can be harsh, leading to material degradation if not properly addressed. Choosing plastics with inherent UV stabilizers or coatings can prolong the lifespan of the components and maintain their appearance.

Another significant factor to consider is the temperature and pressure that the plastics will be subjected to during use. Marine environments can experience extreme temperature fluctuations, and the selected material must maintain its integrity under such conditions. Additionally, the material should exhibit good tensile strength and impact resistance to withstand potential mechanical stresses. Understanding the specific requirements of the marine application, such as weight constraints and thermal properties, will help in selecting the most appropriate plastic materials for optimal performance and safety.

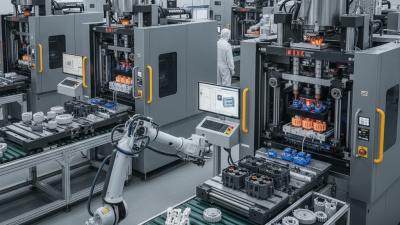

When selecting injection molding plastics for marine applications, it’s essential to consider specific types of materials that can withstand the harsh marine environment. Commonly used plastics include Polyethylene (PE), Polypropylene (PP), and Acrylonitrile Butadiene Styrene (ABS). According to a report by American Chemistry Council, the global market for marine-grade plastics is projected to grow by 6.5% annually, driven by their excellent resistance to water, UV radiation, and chemical corrosion.

Polyethylene is particularly favored for its affordability and high flexibility, making it ideal for various marine components such as boat hulls and fenders. Polypropylene, known for its superior impact resistance, is often used in storage containers and other accessories exposed to rugged marine conditions. Meanwhile, ABS offers excellent toughness and rigidity, making it suitable for structural parts such as housings and frame components. A comprehensive study by the Plastics Industry Association indicates that the durability and longevity of these materials can significantly reduce maintenance costs over the lifespan of marine products.

Additionally, it's important to consider added features such as additives and fillers that enhance performance. For instance, UV stabilizers can be integrated into the molding process, ensuring that the plastic can endure prolonged exposure to sunlight without degrading. Adopting the right injection molding plastic can not only enhance the functionality of marine equipment but also align with industry standards for safety and environmental sustainability.

When selecting plastics for marine applications through injection molding, thorough testing and evaluation are crucial to ensure longevity and performance under harsh conditions. It’s essential to assess the material’s resistance to ultraviolet (UV) radiation, which can cause significant degradation over time. Testing for UV stability typically involves exposing samples to accelerated weathering conditions to simulate long-term exposure. This helps in determining how well the plastic retains its mechanical properties, color, and overall integrity when subjected to sunlight and saltwater.

Another critical aspect of evaluating marine plastics is their resistance to moisture absorption and chemical exposure. Marine environments often consist of varying salinity, which can affect plastic performance. Conducting tests to evaluate the material's water absorption rates and how it reacts to seawater and other chemicals found in marine settings is necessary. These evaluations can involve immersing samples in saltwater for extended periods and measuring changes in weight and dimensions, providing valuable insights into the material's durability and stability in real-world applications. By following these best practices for testing and evaluating marine plastics, designers and manufacturers can make informed choices, ultimately enhancing the reliability and sustainability of their products in marine environments.