When selecting the best Plastic Injection Molding Services, it’s essential to understand the industry’s nuances. “Choosing a provider is more than just price; it's about quality and reliability,” says John Smith, an expert in the field. This insight can guide businesses in making informed decisions.

Plastic injection molding is a complex process. It involves not just machinery, but also skilled professionals. Companies must consider factors like material compatibility and production speed. A provider’s track record can reveal essential details. Can they meet tight deadlines while maintaining quality?

Furthermore, potential clients should examine a service’s customer support. Communication is crucial in handling project changes. Many fail to realize that not all providers will align with their unique needs. Reflecting on these aspects helps ensure a successful partnership in the competitive landscape of Plastic Injection Molding Services.

Plastic injection molding is a widely used manufacturing process. It allows for the production of various parts and products quickly and efficiently. Many industries rely on this process for creating everything from automotive components to consumer goods. This versatility makes it essential to understand how it works.

The process starts with heated plastic being injected into a mold. The plastic then cools and solidifies into the desired shape. This method can produce intricate designs with incredible precision. Many people overlook the importance of mold design, as poor design can lead to defects and wasted materials. Choosing the right service provider becomes crucial to avoid these pitfalls.

Applications of plastic injection molding are vast. From medical devices to household items, nearly every sector uses it. However, there is a growing concern about sustainability. Plastic waste and environmental impact are pressing issues. Many companies are now seeking eco-friendly alternatives. Innovation is key in addressing these challenges, and understanding the nuances of this process will better prepare businesses for the future. There’s still much to learn and improve in the field.

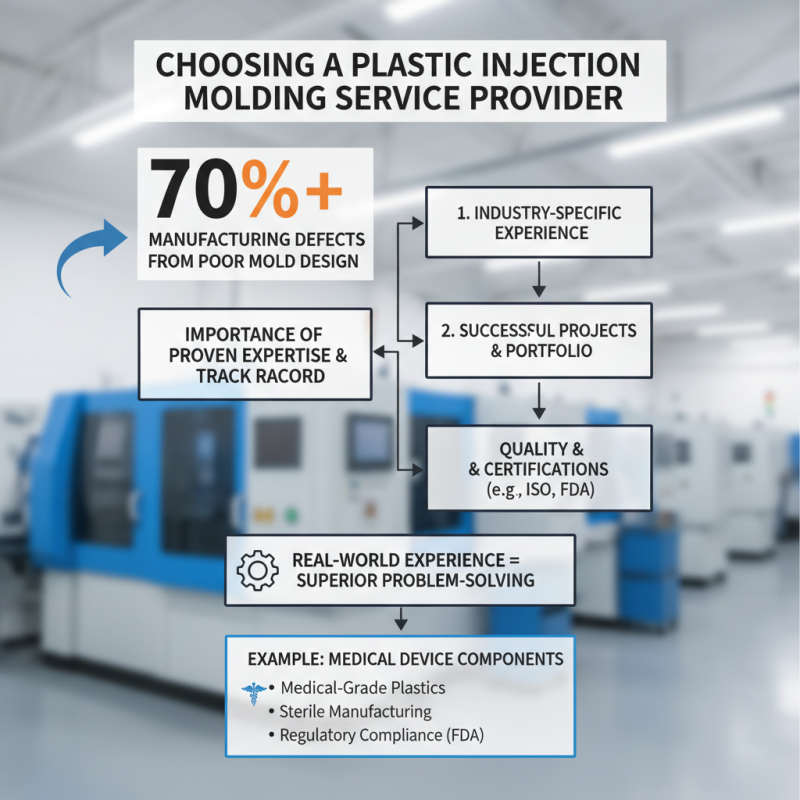

Choosing the right plastic injection molding service provider can be a daunting task. Industry reports show that over 70% of manufacturing defects originate from poor mold design and production. This emphasizes the importance of selecting a provider with proven expertise and a solid track record. Look for companies that have completed successful projects in your industry. Real-world experience often leads to better problem-solving capabilities.

Quality assurance is another crucial factor. According to a study by the American Society for Quality, companies that prioritize quality in their processes see a 20% increase in customer satisfaction. Ask potential providers about their quality control measures. Check if they have certifications like ISO 9001. These certifications indicate a commitment to maintaining high standards.

Consider the technological capabilities of the service provider. Advanced machinery and software can significantly affect production efficiency. Reports indicate that companies using state-of-the-art technology can reduce cycle times by up to 30%. However, not all providers invest in the latest equipment. It’s essential to assess whether their capabilities align with your project requirements. Remember, technology alone does not guarantee success; communication and collaboration during the project are equally important.

When selecting plastic injection molding services, quality standards and certifications are crucial. The ISO 9001 certification is a common benchmark. It ensures that companies consistently meet customer expectations. Studies reveal that 70% of manufacturers strive to maintain this certification. However, not all comply fully. This can lead to inconsistencies in product quality.

Another important certification is ISO/TS 16949. This standard specifically targets the automotive industry. It focuses on reducing variation and waste. Only 25% of injection molding companies in this sector have achieved it. This leaves many consumers at risk of subpar products. Evaluating a company’s commitment to these standards is essential.

Other certifications, like FDA clearance, matter for certain applications. They indicate that materials used are safe for specific industries. Research shows that companies with these certifications tend to have higher customer satisfaction rates. Yet many businesses overlook them in favor of cost savings. This can be a detrimental mistake. Cutting corners may result in legal issues or product recalls.

When evaluating plastic injection molding services, cost comparisons are crucial. Understanding various pricing models helps businesses make informed decisions. For instance, many companies report that the average cost per part ranges significantly. According to industry surveys, costs can vary from $1 to $35 per part based on complexity and volume. This wide range can be disorienting for newcomers.

It's also essential to consider hidden costs. Some services may charge extra for tooling or design changes. A study showed that 30% of businesses experienced unexpected fees during production. This raises the importance of clear communication with your service provider. Ensure all costs are outlined in the initial quote.

Pricing models can differ as well. Some services utilize fixed pricing while others adopt variable models based on production runs. Variable costs can lead to savings, but they require careful monitoring. Companies should analyze their expected volume. A short run may not justify the variable model, leading to increased expenses. Being detail-oriented in your approach can prevent misunderstandings later.

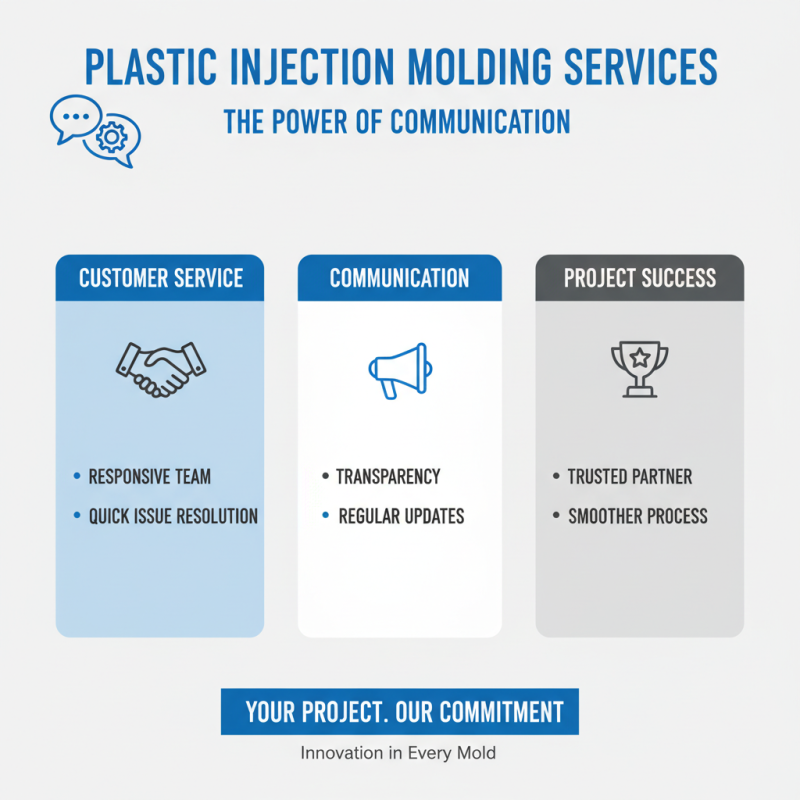

When selecting plastic injection molding services, customer service and communication are vital. They can significantly impact your project’s success. A responsive team can address concerns quickly. Effective communication builds trust, ensuring you're informed throughout the process.

Tips: Ask potential providers about their communication style. Are they available for questions? Do they provide regular updates? Clear answers to these questions can help gauge their commitment. Look for teams that value open dialogue. A collaborative approach fosters innovation and problem-solving.

Not every company excels in communication. Some may overlook your queries or provide unclear responses. This can lead to misunderstandings, frustration, and delays. Reflect on past experiences with suppliers. Did they prioritize your needs? Assess your interactions honestly. The right partner should not only deliver quality products but also make you feel heard and valued.