In today's highly competitive manufacturing landscape, finding the right production method can significantly impact both the cost and quality of your final product. Custom Plastic Injection Molding has emerged as a favored choice for many industries, thanks to its versatility and efficiency. This innovative process allows for the creation of precise, complex components that cater to specific design requirements, which is essential in fields ranging from automotive to consumer electronics. By opting for custom solutions, businesses can not only enhance product performance but also streamline production timelines and reduce waste. In this article, we will explore six compelling reasons to choose Custom Plastic Injection Molding for your next project, ensuring you are well-equipped to make an informed decision that aligns with your manufacturing goals.

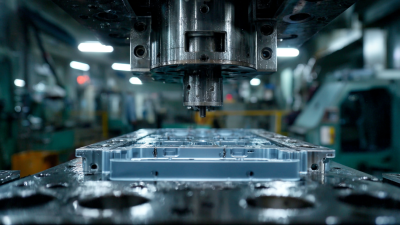

When considering manufacturing methods, custom plastic injection molding presents numerous advantages over traditional techniques. One significant benefit is the ability to achieve intricate designs with high precision. According to a report by the Society of Plastics Engineers, injection molding can produce complex geometries with tolerances as tight as ±0.005 inches, a feat often unattainable with traditional manufacturing methods like machining or hand crafting. This precision not only enhances product quality but also reduces waste, as precise molding minimizes the need for additional material to achieve desired specifications.

Moreover, custom plastic injection molding offers superior efficiency and scalability. The Plastics Industry Association states that this process can yield thousands of parts per hour compared to traditional methods, which often require longer setup times and manual labor. By automating the injection molding process, companies can significantly decrease production costs and timelines, making it an appealing option for large-scale projects. Coupled with the opportunity for enhanced material selection, including various thermoplastics, manufacturers can tailor products to specific needs while maintaining a competitive edge in the market. This combination of efficiency, precision, and material versatility positions custom plastic injection molding as a leading choice in modern manufacturing.

When considering manufacturing options, custom plastic injection molding stands out for its cost-effectiveness, particularly for large production runs. This method allows you to produce high volumes of parts rapidly while maintaining precision and consistency. The initial investment in mold design can be high, but when spread over thousands of units, the per-part cost decreases significantly. This efficiency not only saves money but also time, ensuring you meet tight deadlines without sacrificing quality.

Tip: To maximize your return on investment, carefully plan your design to minimize complexity. Simplifying the design reduces the need for intricate molds, which can be costly and time-consuming to produce.

Additionally, working closely with your injection molding partner can lead to further savings. They can provide insights into material selection and production techniques that optimize both cost and performance.

Tip: Always consider the total cost of ownership, including raw materials and labor. Choosing the right resin can greatly affect your overall budget and end product quality, so research and collaboration are key.

Custom plastic injection molding offers unparalleled design flexibility, making it a superior choice over standard molding options. With custom molding, you can create complex shapes and intricate details that are tailored specifically to your project's requirements. This level of customization allows for enhanced functionality and aesthetic appeal, giving your product a competitive edge in the market.

When considering custom plastic injection molding, keep in mind these essential tips: First, collaborate closely with your design and engineering teams to ensure your specifications are achievable within the molding process. Second, utilize 3D modeling to visualize your design before the production phase; this helps identify potential issues early on. Finally, choose a reputable injection molding partner who understands your vision and can provide valuable insights into materials and techniques that will optimize both the design and manufacturing phases.

The ability to use different materials and finishes with custom molds further enhances design flexibility, enabling you to cater to specific market needs and customer preferences. By opting for custom plastic injection molding, you are not just making a product; you are crafting a solution that addresses unique challenges while elevating your brand’s identity.

| Reason | Description | Benefits |

|---|---|---|

| Design Flexibility | Custom molds allow for intricate designs that standard molds cannot achieve. | Increased creativity in design, tailored to specific project requirements. |

| Cost Efficiency | While the initial investment may be higher, long-term savings are notable. | Reduced per-unit costs for large production runs. |

| Material Variety | Access to a wider range of materials, including specialty plastics. | Enhanced performance characteristics for specific applications. |

| Precision and Accuracy | Custom molds provide high precision, resulting in less waste and rework. | Improved product consistency and quality assurance. |

| Scalability | Easily scale production up or down based on market demand. | Flexible response to changing production needs. |

| Reduced Lead Times | Streamlined processes result in shorter project timelines. | Faster time to market for new products. |

Quality control and precision are paramount in the realm of custom plastic injection molding, making it a preferred choice for manufacturers seeking reliability and excellence. The process begins with meticulous design specifications, allowing engineers to create molds that accurately reflect the desired product dimensions and features. This level of precision reduces the likelihood of defects during production, ensuring that each batch meets stringent quality standards.

Moreover, the integration of advanced technology in injection molding further enhances quality control. For instance, real-time monitoring systems can track temperature, pressure, and material flow within the molding machine, allowing for immediate adjustments as needed. This proactive approach helps in minimizing variations and ensures consistency across all manufactured parts. By investing in custom plastic injection molding, companies can achieve not only superior product quality but also enhance their overall operational efficiency, reducing waste and costs associated with rework and defects.

When considering custom plastic injection molding for your next project, sustainability and material efficiency should be top priorities. One of the key benefits of this manufacturing method is its ability to minimize waste. During the injection molding process, materials are precisely measured and injected into molds, ensuring that little excess material is produced. This not only reduces costs but also lessens the environmental impact associated with waste management. What's more, many injection molding companies are now utilizing recyclable and biodegradable materials, making it easier to align production practices with sustainable goals.

Additionally, custom plastic injection molding allows for better material efficiency through the use of advanced technologies. Modern injection molding machines are designed to optimize energy consumption and reduce the carbon footprint of the manufacturing process. By investing in custom molds, businesses can achieve complex designs that utilize materials more effectively, allowing for lightweight yet durable products. Ultimately, embracing sustainability and material efficiency in custom plastic injection projects not only benefits the environment but also positions a brand as a leader in responsible manufacturing.