Golf Cart Plastic Injection Molding has become a critical process in the golf cart industry. According to John Smith, an expert in manufacturing and molding techniques, “The right injection molding methods can make or break the quality of golf carts.” This emphasizes the need for precision and expertise in production.

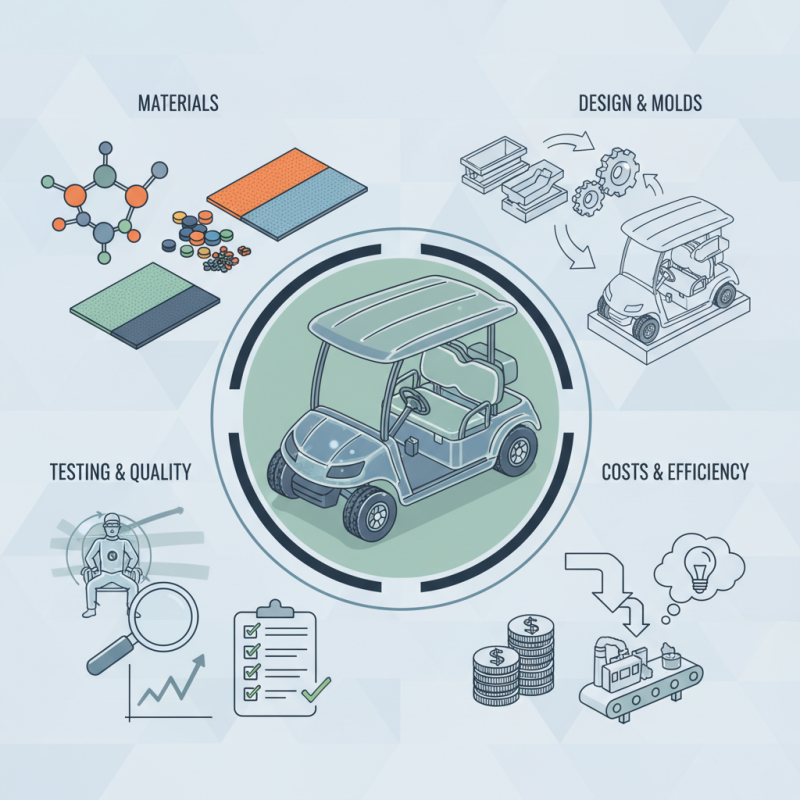

Efficient usage of Golf Cart Plastic Injection Molding requires attention to detail. The choice of materials affects durability and performance. With various designs available, it’s essential to select the right mold for effective outcomes. Many manufacturers underestimate the importance of testing. Without thorough evaluation, issues may arise later in the production cycle.

Furthermore, production costs can escalate without careful planning. Suboptimal designs or materials lead to waste and inefficiencies. Continuous improvement in mold design and production methods is necessary. Reflecting on past decisions can unveil areas for enhancement. Ultimately, mastering Golf Cart Plastic Injection Molding can yield significant benefits when approached with thoughtfulness and skill.

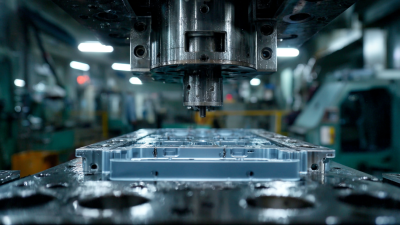

Understanding Golf Cart Plastic Injection Molding Basics involves grasping essential concepts of the process. This method uses high pressure to inject molten plastic into a mold. It enables manufacturers to create various components efficiently. The global plastic injection molding market is projected to reach $400 billion by 2026, demonstrating its significance in the industry.

Many parts in golf carts can benefit from this technique. Handlebars, dashboards, and seat backs are just a few examples. A report from Grand View Research highlights that the automotive sector accounts for roughly 30% of injection molding applications. This assertion emphasizes how critical this method is for producing durable and lightweight automotive parts.

Yet, challenges exist. The need for precise temperature control is paramount. Incorrect settings can lead to defects. Moreover, material selection is complicated. Different plastics can affect durability and weight. These factors must be considered carefully to optimize production. Mistakes here can lead to higher costs and longer lead times. Proper training and experience are essential for success in this field.

When deciding on materials for golf cart components, it is crucial to consider both durability and weight. Common choices include ABS and polypropylene. ABS offers strength and resistance to impacts. It can withstand rough handling during transportation. Polypropylene, on the other hand, is lightweight and resistant to moisture. This makes it ideal for exterior parts.

However, not all materials perform well under every condition. For instance, while ABS is tough, it may become brittle in extremely cold weather. Similarly, polypropylene can warp under high temperatures. This necessitates careful application. Testing different blends and additives might help achieve optimal results.

Moreover, the finishing process can influence the final product. Factors like color, texture, and glossiness matter. A matte finish might appeal more aesthetically in certain markets. Yet, achieving uniformity can be challenging. Adjustments during the molding process are often required. Each decision must be weighed carefully to ensure the best outcome.

This chart illustrates the percentage of different materials commonly used in the injection molding process for golf cart components. The selection of materials is crucial for achieving durability, weight efficiency, and cost-effectiveness in manufacturing.

When considering golf cart plastic injection molding, design factors play a crucial role in the final outcome. Material choice is significant; it can influence durability and aesthetics. Optimize the plastic selection based on the environmental conditions the cart will face. Choose a lightweight resin for better performance but ensure it retains strength.

Mold design should also be approached with caution. Complex shapes can lead to production delays. Ensure that your design includes proper draft angles to facilitate de-molding. Yet, avoiding excess complexity might compromise the visual appeal. Balancing functionality with aesthetics is always a challenge.

Prototypes are essential in this process. They allow for practical testing of designs. However, the first prototype often reveals hidden flaws. This can be a learning opportunity for iterations. Continual refinement can help achieve better mold efficiency. Keep in mind that not every idea will work perfectly, and that's part of the journey.

| Design Consideration | Importance | Best Practices |

|---|---|---|

| Material Selection | Critical for durability and performance | Choose UV-resistant materials |

| Mold Design | Directly impacts production efficiency | Incorporate proper draft angles |

| Cooling System | Effects cycle time and part quality | Optimize cooling channels for efficiency |

| Flow Rate | Affects the uniformity of the part | Control injection speed accordingly |

| Finishing Options | Enhances aesthetic appeal and functionality | Consider texture and coating methods |

In the world of golf cart manufacturing, optimizing production efficiency is crucial. Injection molding, a key process, can impact both cost and quality. To enhance efficiency, manufacturers should focus on precise temperature control. This ensures that the plastic melts evenly, reducing defects in the final product. It’s essential to calibrate machines regularly, as even minor errors can accumulate, leading to waste.

Another area to consider is the design of molds. A well-designed mold not only speeds up production but also reduces cycle times. Complex shapes may seem appealing, but they can complicate the molding process. Re-visiting design iterations helps identify potential challenges early. Many teams overlook this step, resulting in delays and increased costs.

Quality control plays a vital role in maintaining production efficiency. Continuous monitoring during the injection process is necessary. Skipping checks can lead to unnoticed flaws that accumulate over time. Understanding the balance between speed and quality is essential. Each adjustment in the process should be tested thoroughly, as some changes may yield unexpected results.

Quality control is crucial in golf cart plastic injection molding. Maintaining consistency in part quality ensures the functionality and longevity of golf carts. One effective measure involves setting clear specifications for each part. These specifications must detail dimensions, colors, and materials. Regular monitoring can help identify deviations before they become significant issues.

Another important aspect is the inspection of finished parts. Visual checks for defects like warping or discoloration should be routine. Utilizing precision measuring tools will also enhance the accuracy of inspections. However, relying solely on machine inspections can lead to oversight. Human evaluations can often catch subtle flaws that machines may miss.

Training workers is vital to maintaining quality. Proper training helps employees recognize potential problems early in the production process. Continuous feedback loops encourage a culture of accountability. Still, it is essential to regularly review and revise quality protocols. This makes sure that everyone stays updated on best practices. Quality control in plastic injection molding for golf carts is a continuous journey of improvement and vigilance.