Injection molding is a cornerstone of the manufacturing industry, responsible for producing an estimated 30% of all plastic products today, according to the Plastics Industry Association. As companies increasingly rely on this versatile process to meet demand across various sectors, including automotive, consumer goods, and medical, mastering injection molding techniques has never been more critical.

A comprehensive understanding of factors such as material selection, mold design, and process optimization can significantly influence production efficiency and product quality. Reports indicate that maximizing efficiency in injection molding operations can lead to up to a 15% reduction in operational costs, highlighting the importance of honing skills and techniques in this area.

A comprehensive understanding of factors such as material selection, mold design, and process optimization can significantly influence production efficiency and product quality. Reports indicate that maximizing efficiency in injection molding operations can lead to up to a 15% reduction in operational costs, highlighting the importance of honing skills and techniques in this area.

As we delve into the essential tips for mastering injection molding, these insights will empower professionals to navigate the complexities of this technology and achieve superior results in their projects.

Choosing the right materials for injection molding is crucial for achieving optimal results in any project. Various plastics and composites are available, and each material offers unique properties that can influence the performance, durability, and aesthetic of the final product. For instance, thermoplastics such as ABS and polypropylene are popular choices due to their versatility and ease of processing. They can be molded into intricate shapes, making them ideal for components in automotive, consumer goods, and electronic applications.

When selecting materials, it’s vital to consider the specific requirements of your application. Factors such as temperature resistance, mechanical strength, and environmental exposure should guide your choice. Additionally, understanding the differences between materials can help you avoid common pitfalls, such as selecting a material that becomes brittle under stress or one that warps under heat. By carefully evaluating your needs and conducting thorough material research, you can ensure that your injection molding projects are successful and yield high-quality, reliable products.

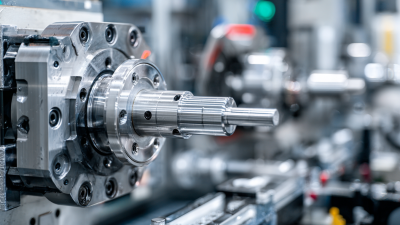

Understanding the settings of an injection molding machine is crucial for achieving precision in your molded parts. Proper calibration of temperature, pressure, and cycle time can significantly impact the quality of your final product. For instance, maintaining the correct barrel temperature ensures that the material is melted uniformly, reducing the chances of defects such as warping or incomplete fills.

Tip: Always monitor the injection speed. A higher injection speed can minimize the appearance of sink marks, while a slower speed can enhance the detailing of intricate designs.

Additionally, adjusting the hold pressure is essential for maintaining the integrity of the mold cavity. It helps in compensating for material cooling and shrinkage while ensuring that the final part remains dimensionally stable.

Tip: Don’t overlook the importance of cooling time. Adequate cooling allows the material to solidify properly, preventing warping and ensuring dimensional accuracy in your parts. By following these tips, you can master the art of injection molding and optimize your production process.

Proper maintenance of injection molding equipment is crucial for ensuring optimal performance and longevity. Regular inspections and routine maintenance procedures can greatly reduce the likelihood of breakdowns and costly repairs. Operators should develop a comprehensive maintenance schedule that includes checking hydraulic systems, lubricating moving parts, and cleaning melt channels to keep the machinery in top condition. Additionally, monitoring the temperature controls and verifying the integrity of molds will enhance the consistency and quality of the molded products.

Proper maintenance of injection molding equipment is crucial for ensuring optimal performance and longevity. Regular inspections and routine maintenance procedures can greatly reduce the likelihood of breakdowns and costly repairs. Operators should develop a comprehensive maintenance schedule that includes checking hydraulic systems, lubricating moving parts, and cleaning melt channels to keep the machinery in top condition. Additionally, monitoring the temperature controls and verifying the integrity of molds will enhance the consistency and quality of the molded products.

Another essential practice is to train personnel on the importance of maintaining machinery. Workers who understand how to identify signs of wear or malfunction can address issues before they escalate. Implementing a system for logging maintenance activities helps track performance over time and can provide insights into patterns that may indicate the need for more extensive repairs. By prioritizing these essential maintenance practices, manufacturers can extend the lifespan of their injection molding equipment, ensuring efficiency and productivity in their operations.

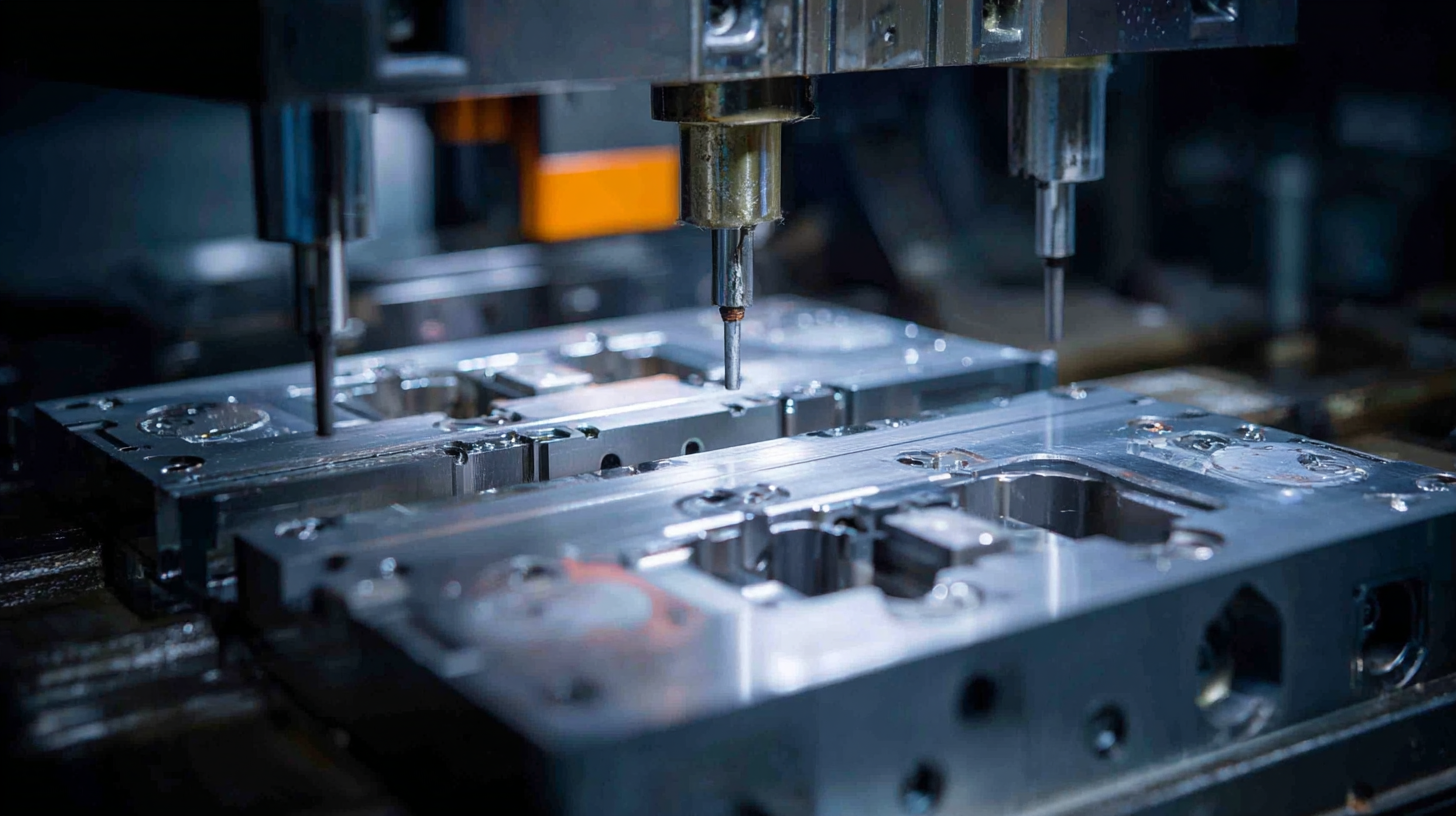

In the world of injection molding, efficient mold design is crucial for optimizing production efficiency and reducing waste. According to the 2022 “Injection Molding Market Analysis” report by Grand View Research, the global injection molding market is expected to reach $338.3 billion by 2027, largely driven by advancements in mold design and technology. To achieve this efficiency, it is essential to prioritize the use of simulation software during the design phase. Such tools can predict flow characteristics and help engineers identify potential issues, allowing for adjustments before physical prototypes are made, which can significantly cut costs and lead times.

Additionally, incorporating Modular Molds can enhance flexibility and reduce downtime. A study from the Society of Plastics Engineers highlights that utilizing modular designs can decrease mold changeover time by up to 40%. This allows manufacturers to swiftly adapt their production lines to different product requirements without the need for extensive retooling, thereby maximizing uptime and meeting customer demands efficiently. Ultimately, investing in intelligent design techniques and using the latest engineering software not only enhances production rates but also improves product quality in the highly competitive injection molding industry.

When it comes to injection molding, understanding common defects and their solutions is crucial for achieving high-quality results. Among the most prevalent issues are sink marks, which occur when the part cools unevenly. To address this, it's essential to optimize cooling time and adjust mold temperature to ensure uniform heat distribution. Additionally, increasing the pack pressure can help mitigate the formation of sink marks.

Another defect frequently encountered is short shots, where the molded part doesn't fill completely. This can be remedied by increasing the injection speed or altering the material feed to ensure a consistent flow. Utilizing proper venting in the mold design can also alleviate this problem by allowing air to escape efficiently during the injection process.

Here are a couple of tips to enhance your mastery of injection molding techniques: First, always ensure the resin material is dry prior to use to prevent moisture-related defects. Second, routinely maintain your molds and machinery to keep the system in optimal condition, which directly impacts the quality of your final products. By being proactive about these common defects and their solutions, you can significantly improve your injection molding outcomes.