As the automotive industry continues to evolve, the significance of innovative manufacturing processes becomes increasingly paramount. The 138th Canton Fair in 2025 presents a unique opportunity to delve into the advancements in Plastic Injection Molding Automotive Parts, a crucial technology that underpins modern vehicle production. This event will showcase cutting-edge techniques and materials that enhance the efficiency, durability, and sustainability of automotive components. Attendees will witness firsthand how these innovations are set to revolutionize the industry, addressing the growing demands for lightweight, cost-effective, and high-performance parts.

By exploring the future of Plastic Injection Molding Automotive Parts, the Canton Fair aims to connect industry leaders, foster collaboration, and drive the next wave of automotive innovation, setting the stage for a more dynamic and resilient market.

The 138th Canton Fair in 2025 is set to be a pivotal event for the automotive industry, particularly in the realm of plastic injection molding. Key trends emerging from the fair highlight the growing adoption of sustainable materials in the production of automotive parts. Manufacturers are increasingly focusing on eco-friendly resins that not only meet regulatory standards but also cater to the consumer demand for environmentally responsible products. This shift towards sustainability is expected to enhance the market competitiveness of companies that prioritize green practices.

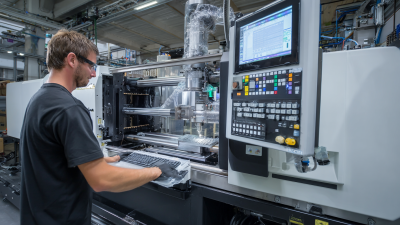

Moreover, advancements in technology are revolutionizing plastic injection molding processes. Innovations such as automation and smart manufacturing techniques are streamlining production lines, reducing waste, and improving efficiency. Industry leaders are showcasing state-of-the-art machinery capable of producing highly complex components with precision. These developments indicate a future where rapid prototyping and customization will become the norm, allowing automotive companies to respond more swiftly to changing consumer preferences while maintaining high-quality standards. This dynamic environment at the Canton Fair underscores the critical role of plastic injection molding in shaping the future of the automotive sector.

The automotive industry is on the verge of transformation, particularly through innovative technologies in plastic injection molding. With the global injection molding market projected to reach USD 211 billion by 2034, the shift towards advanced manufacturing processes, such as micro-injection molding and multi-component molding, is pivotal. These technologies are not only enhancing the precision and efficiency of part production but also aligning with the industry's growing demand for lightweight materials, which are essential for improving fuel efficiency and reducing emissions.

In line with this trend, the automotive plastics market is anticipated to expand significantly, reaching approximately USD 76.6 billion by 2032, growing at a CAGR of 7.8% from 2025. This surge is primarily driven by the adoption of cost-effective solutions and cutting-edge manufacturing technologies. The 138th Canton Fair in 2025 will serve as a critical platform to showcase these advancements, highlighting how the integration of innovative plastic injection molding techniques can lead to more sustainable and versatile automotive components, ultimately shaping the future of automotive engineering.

The automotive industry is undergoing a significant transformation as it increasingly embraces sustainability within its manufacturing processes. Plastic injection molding, a key method for producing automotive parts, presents unique challenges and opportunities in this regard. According to a report by the Plastics Industry Association, approximately 25% of all plastic used in automotive applications can be recycled, highlighting the potential for circular economy principles to revolutionize production practices. The 138th Canton Fair 2025 will provide a platform for manufacturers to explore innovative strategies that enhance the sustainability of plastic injection molding.

One of the main challenges in achieving sustainability is the reliance on traditional petroleum-based plastics, which contribute to environmental degradation. However, advancements in bioplastics and the development of sustainable polymers from renewable sources are paving the way for a greener future. A recent study by Research and Markets indicated that the global bioplastics market is expected to reach USD 44 billion by 2026, driven by increasing regulatory pressures and consumer demand for environmentally-friendly products. At the Canton Fair, stakeholders will likely discuss these emerging materials and their viability in high-volume automotive applications, focusing on reducing carbon footprints while maintaining performance and safety standards.

This chart illustrates the projected usage trends for various materials in plastic injection molding for automotive parts by the year 2025. The focus on sustainability shows a shift towards recycled and bio-based plastics while traditional plastics remain prevalent.

The upcoming 138th Canton Fair in 2025 is set to be a pivotal event for automotive part manufacturers, providing valuable networking opportunities within the rapidly evolving market of plastic injection molding. According to a report by Research and Markets, the global automotive plastic injection molding market is expected to reach $39.8 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.5%. This growth underscores the importance of networking and collaboration among manufacturers to adapt to emerging technologies and sustainability practices.

At the Canton Fair, industry professionals will have the chance to connect with key players, exchange insights, and explore innovative solutions that enhance efficiency in production. The event will host a variety of exhibitors specializing in modern materials and manufacturing techniques, including eco-friendly plastics that align with global trends towards sustainability. With the automotive sector increasingly prioritizing lightweight components to improve fuel efficiency, the demand for advanced plastic injection molded parts is greater than ever. Engaging with peers at the fair can provide manufacturers with the insights needed to stay competitive and meet the challenges of a dynamic market landscape.

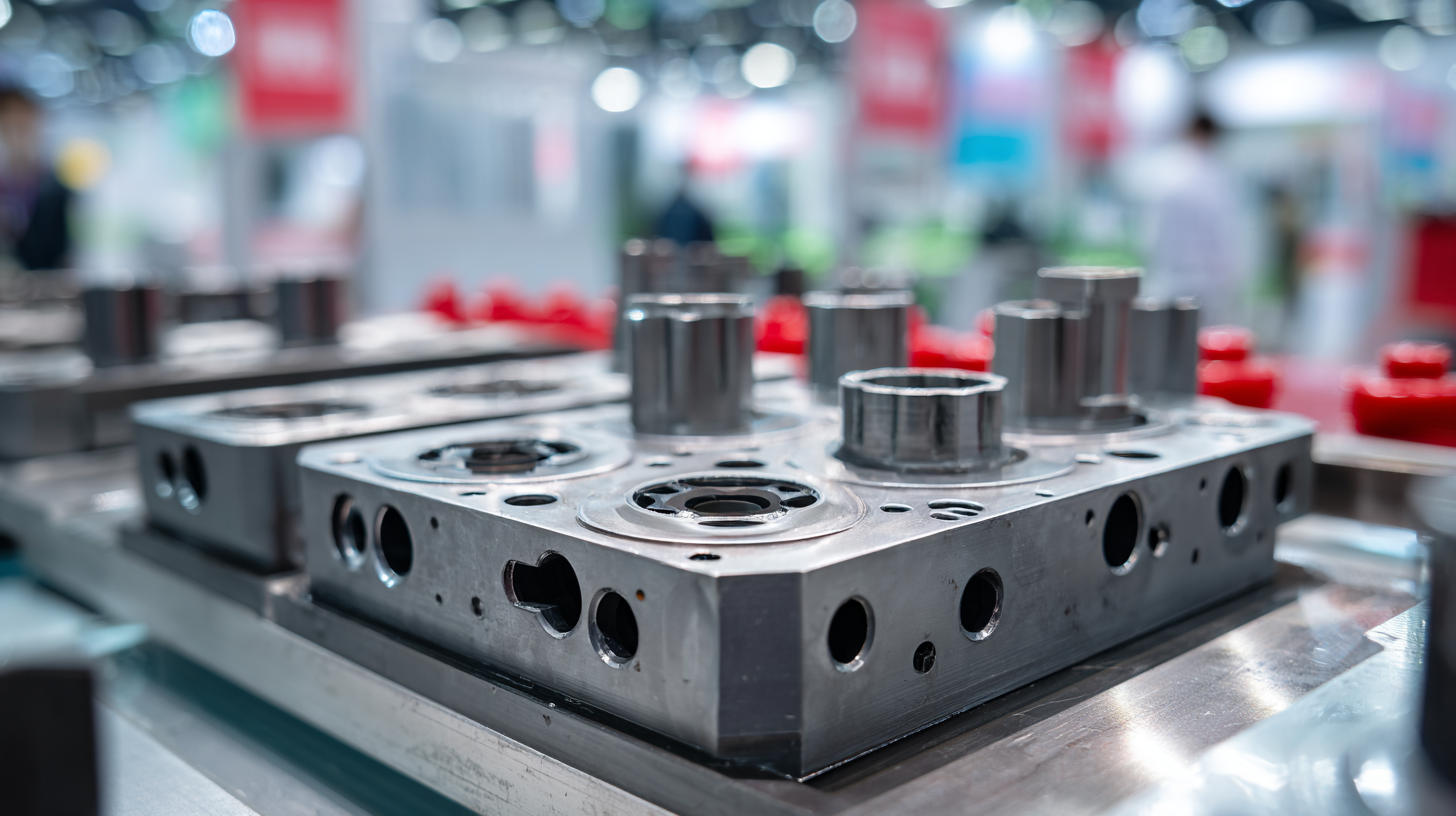

The automotive industry is undergoing a significant transformation, with plastic injection molding emerging as a key technology for producing sustainable and efficient parts. Case studies from various automotive manufacturers illustrate how this technique not only optimizes production processes but also enhances the performance of automotive components. For instance, companies are leveraging advanced materials and innovative molding techniques to create lightweight, durable parts that contribute to overall vehicle efficiency and sustainability.

One notable application can be seen in the production of intricate dashboard components, where precision and aesthetics are crucial. Manufacturers have successfully utilized plastic injection molding to produce complex geometries that reduce weight without compromising strength. Moreover, as the automotive sector increasingly focuses on eco-friendly solutions, case studies demonstrate how recyclability and reduced material waste achieved through modern molding practices align with industry sustainability goals, paving the way for future developments in the field.