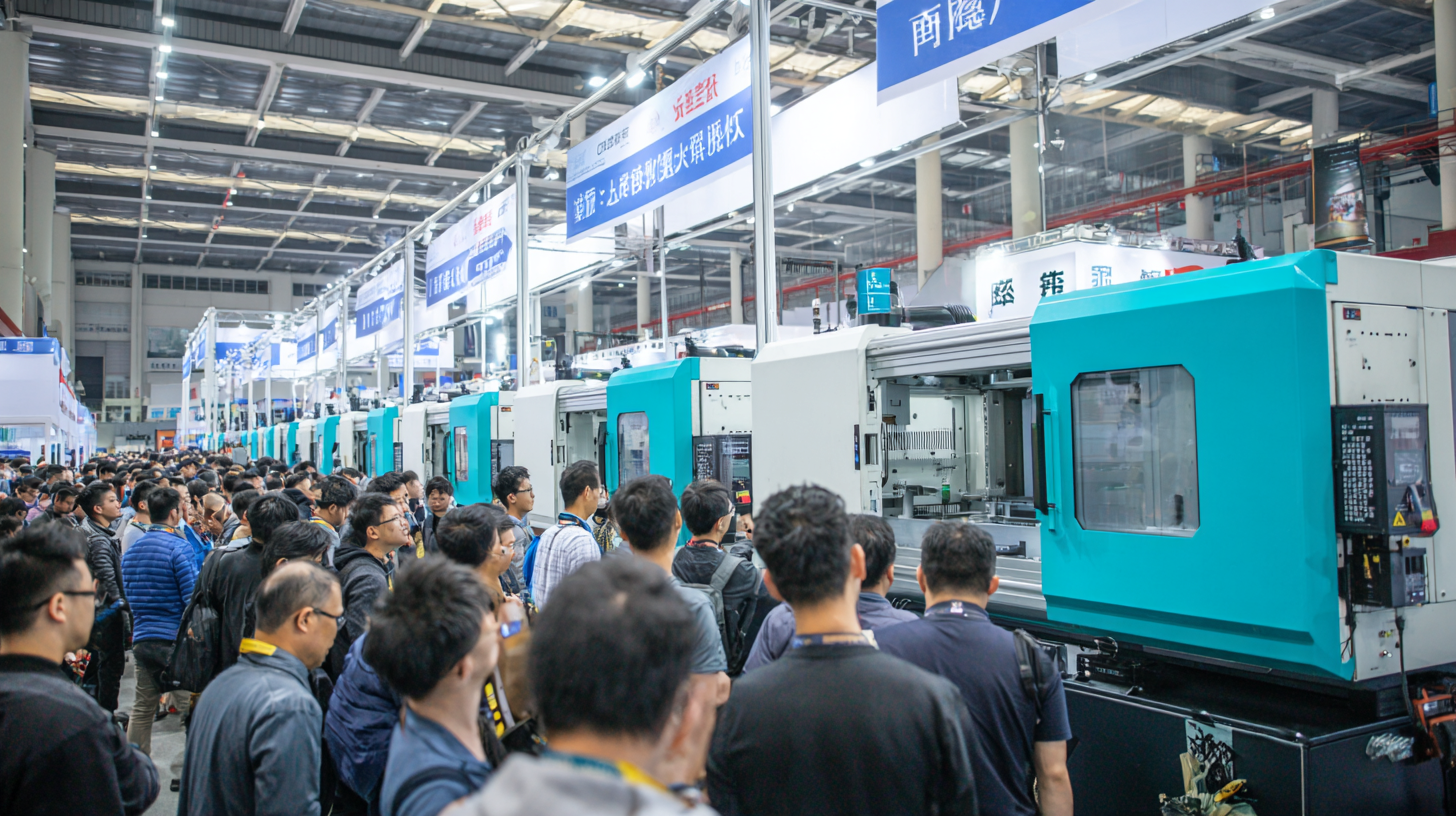

The 2025 China Import and Export Fair, also known as the 138th Canton Fair, presents a significant opportunity to examine the evolving landscape of the automotive industry, particularly through the lens of Plastic Injection Molding Automotive Parts. As the automotive sector increasingly embraces innovative manufacturing techniques, plastic injection molding has emerged as a pivotal method for the production of lightweight, durable, and cost-effective components. This introduction to the fair will spotlight the advancements in technology, sustainability practices, and market trends associated with plastic injection molding in automotive applications. Participants and exhibitors will gather to showcase their latest products and innovations, highlighting how these materials and processes can enhance vehicle performance and meet growing consumer demands. As the global push for efficient and environmentally-friendly solutions intensifies, understanding the role of plastic injection molding in shaping the future of automotive parts is more crucial than ever.

The automotive sector is poised for significant growth in plastic injection molding by 2025, driven by the increasing demand for lightweight, durable, and cost-effective components. According to a report by MarketsandMarkets, the global plastic injection molding market is projected to reach USD 280 billion by 2025, with the automotive segment expected to expand at a compound annual growth rate (CAGR) of 4.5%. This growth is largely attributed to the automotive industry's shift towards advanced manufacturing techniques that improve efficiency and reduce production costs.

As automotive manufacturers increasingly adopt electric vehicles (EVs), the need for innovative plastic components will surge. The Freedonia Group estimates that the use of molded plastics in the automotive market will grow at a rate of 5% annually as manufacturers strive to maximize fuel efficiency and meet stringent emissions regulations. Additionally, the ongoing advancements in polymers and composite materials will further enhance the performance and sustainability of automotive parts, making plastic injection molding an integral part of the industry's future. The 2025 China Import and Export Fair will serve as a pivotal platform for industry stakeholders to showcase these innovations and discuss the future trajectory of plastic injection molding in automotive applications.

The automotive sector is witnessing remarkable growth in the demand for plastic injection molded parts, driven by the increasing need for lightweight, durable, and cost-effective materials. By 2025, the market for nylon 66 is projected to reach approximately $45.17 million, highlighting the material's pivotal role in the automotive industry. Its unique properties, including high processability, strength, and toughness, make nylon 66 a preferred choice for various automotive applications. This trend is expected to continue, with the market expanding significantly, reflecting a compound annual growth rate (CAGR) of 6.24% until 2033.

Moreover, the shift towards electric vehicles and the emphasis on reducing vehicle weight is further propelling the use of modified plastics. The ongoing research and development efforts in the automotive molding market indicate a growing recognition of the benefits of utilizing advanced materials. The establishment of standardized protocols across multiple industries showcases the sustained commitment to innovation and excellence in automotive manufacturing processes, ensuring that manufacturers stay competitive in a rapidly evolving marketplace.

The rise of sustainability initiatives is significantly shaping the plastic injection molding sector, particularly within the automotive industry. A recent study by the Grand View Research estimates that the global plastic injection molding market is projected to reach approximately $451.5 billion by 2027, with automotive applications contributing a substantial share. This growth is driven by manufacturers' increasing focus on eco-friendly materials and processes, aligning with global efforts to reduce carbon emissions and enhance resource efficiency.

Technological advancements in plastic injection molding have changed the landscape, allowing for innovations such as the use of recycled plastics and biopolymers. According to a report by the Plastics Industry Association, the incorporation of sustainable practices could potentially decrease the energy consumption of injection molding by up to 30%. Furthermore, as more automotive companies commit to using recycled materials in their production lines—reflecting a commitment to circular economy principles—the market is expected to evolve, encouraging broader adoption of sustainable molding technologies. This transformation will be central to automotive manufacturers’ strategies at events like the 2025 China Import and Export Fair, showcasing how sustainability can drive industry growth while addressing environmental concerns.

The 2025 China Import and Export Fair presents a significant opportunity for stakeholders in the automotive parts sector, particularly those involved in plastic injection molding. As the automotive industry evolves, manufacturers are increasingly recognizing the advantages of utilizing plastic components to enhance vehicle performance, reduce weight, and lower production costs. This trade fair will serve as a platform for industry players to showcase innovative injection molding technologies and explore new partnerships, both locally and internationally.

The 2025 China Import and Export Fair presents a significant opportunity for stakeholders in the automotive parts sector, particularly those involved in plastic injection molding. As the automotive industry evolves, manufacturers are increasingly recognizing the advantages of utilizing plastic components to enhance vehicle performance, reduce weight, and lower production costs. This trade fair will serve as a platform for industry players to showcase innovative injection molding technologies and explore new partnerships, both locally and internationally.

Additionally, attending this fair enables businesses to gain insights into emerging trends and consumer demands in the automotive sector. Participants can engage in discussions around sustainable practices and the shift towards electric vehicles, which often require specialized plastic components for battery housing and lightweight structures. By leveraging the opportunities presented at this event, companies can strategically position themselves in the market, catering to the growing demand for advanced automotive parts while fostering collaborations that enhance their competitive edge.

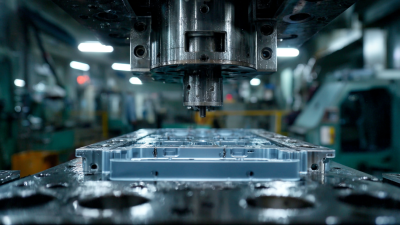

The automotive industry has witnessed significant transformation with the advent of plastic injection molding techniques, providing an alternative to traditional manufacturing methods. Plastic injection molding stands out for its ability to produce complex shapes with high precision, enabling manufacturers to create lightweight automotive parts that can enhance fuel efficiency. In contrast, traditional manufacturing methods, such as stamping and machining, often result in heavier components requiring more energy to operate. As the industry moves toward sustainability, the lightweight nature of injection-molded parts presents a compelling argument for their increased adoption.

Moreover, the efficiency of plastic injection molding allows for faster production cycles and reduced waste. With the ability to produce large volumes of parts in a consistent manner, manufacturers can meet the growing demand for automotive components without compromising on quality. Traditional methods, while beneficial in certain contexts, generally involve more physical labor and longer setup times, making them less adaptable to rapid market changes. As the 2025 China Import and Export Fair showcases advancements in this field, the comparison between these techniques highlights the shifting paradigms in automotive manufacturing toward newer, more sustainable methodologies.

The chart compares the production efficiency between plastic injection molding and traditional manufacturing methods in automotive parts. Plastic injection molding shows a significantly higher output, producing 150 units per hour compared to 80 units per hour from traditional methods, highlighting its advantages in the automotive industry.