Injection Molding Golf Cart Parts is a fascinating process. It plays a crucial role in manufacturing. This technique helps create durable and efficient cart components.

Golf carts require specific parts for great performance. Injection molding provides precision in making these parts. The process molds plastic into desired shapes, ensuring consistency each time. However, precision also comes with challenges.

Sometimes, defects occur during manufacturing. Quality control is essential to avoid issues. Companies must continuously refine their techniques. This reflection on improvement drives innovation in golf cart part production.

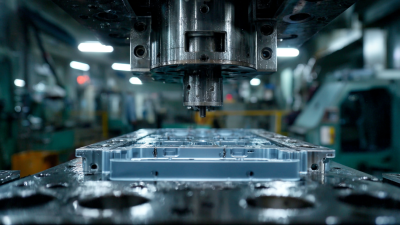

Injection molding is a popular process for producing golf cart parts. It involves heating plastic until it melts. This molten plastic is then injected into a mold. Once cooled, the plastic solidifies into the desired shape. This method is efficient and can create complex designs.

Understanding injection molding helps in realizing its significance. The molds used can be expensive. Yet, they allow for mass production of parts with consistent quality. This is crucial for parts like dashboards, bumpers, and battery trays. The precision of the molds ensures that the parts fit perfectly in every cart. However, the initial investment can be daunting for small manufacturers.

There are challenges to consider. For instance, if a mold is not designed well, it can lead to defects. Quality control measures are essential in this process. Over time, manufacturers may find the need to modify designs. This iterative process can be both rewarding and frustrating. Balancing cost and quality remains a constant challenge. Understanding these dynamics is vital for anyone involved in the industry.

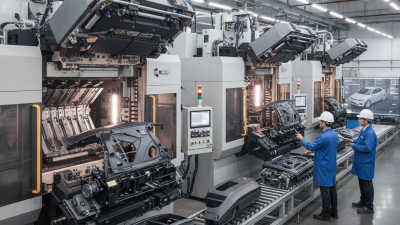

Injection molding is a key technique for producing golf cart parts. The process is efficient and offers precision. It involves several steps. First, raw plastic pellets are heated until they melt. Next, the melted plastic is injected into a mold. This mold shapes the part as it cools and solidifies.

After the cooling phase, the mold opens to release the newly formed part. According to industry reports, injection molding can produce thousands of parts in a single run. This capability significantly reduces costs. However, the initial setup can be expensive and time-consuming.

Maintaining quality is essential. Even slight variations in temperature can affect the final product. Some parts may require additional finishing processes. Overall, while injection molding is effective, it also presents challenges that need careful management. The balance of efficiency and quality is critical in this manufacturing method.

Injection molding is a widely used manufacturing process, especially for producing golf cart parts. Selecting the right materials is crucial. Plastics dominate this space due to their durability and versatility.

Common materials include ABS, a tough plastic known for its impact resistance. It withstands rough conditions and holds up well under various temperatures. Polypropylene is another option. It’s lightweight and flexible, making it ideal for components that require bending or slight deformation.

Other materials like nylon offer strength and abrasion resistance. This makes it suitable for parts that face friction. However, each material has its drawbacks. For instance, UV exposure can weaken plastics over time. This leads to fading and brittleness. Manufacturers need to consider these trade-offs during the design phase. Reflecting on material choices can lead to better performance and longevity of golf cart components.

Injection molding is a widely used process in the production of golf cart parts. This method involves creating parts by injecting molten material into molds. It allows for the production of complex shapes with high precision. Golf cart components, such as dashboards, bumpers, and seats, often benefit from this technique.

One of the key advantages of injection molding is efficiency. The process can produce large quantities of parts quickly. Cycle times are short, which maximizes output. Cost-per-unit decreases as production scales up. However, the initial investment for molds can be high. This upfront cost might deter small manufacturers. They often end up using alternative methods that may not provide the same level of quality.

Moreover, injection molding offers design flexibility. It allows for intricate details and smooth finishes that enhance the aesthetic appeal of parts. However, achieving the perfect design takes time and effort. Some manufacturers find it challenging to balance creativity and practicality. There can be a steep learning curve in perfecting designs for injection molding. Mistakes may lead to wasted materials and time, prompting continuous improvement.

| Dimension | Details |

|---|---|

| Material Types | ABS, Polypropylene, Polyethylene |

| Typical Cycle Time | 30 to 60 seconds |

| Production Volume | High volume, thousands of parts per day |

| Cost Efficiency | Lower cost per part with increased production |

| Design Flexibility | Complex geometries and custom designs possible |

| Material Waste | Minimal waste compared to other manufacturing methods |

| Surface Finish | High-quality surface finishes achievable |

| Lead Time | Short lead times after initial setup |

Injection molding is a key manufacturing process for creating various components in golf carts. The technology enables manufacturers to produce complex shapes with precision and efficiency. According to a recent industry report, around 30% of golf cart parts are now made using injection molding techniques.

There are several common applications for injection molded parts in golf carts. Dashboard components often rely on this method for an accurate fit and finish. The lightweight but durable material allows for easy integration into different designs. Additionally, components such as seating, body panels, and storage compartments benefit from injection molding’s versatility. These parts require a robust solution that withstands the wear and tear of outdoor use.

However, there's room for improvement. Some manufacturers face challenges regarding material consistency during the injection molding process. Variability can lead to defects, affecting overall product reliability. Additionally, recycling and eco-friendliness remain concerns. Studies show that around 25% of plastic waste comes from such manufacturing processes. Addressing these issues could enhance sustainability in the golf cart industry.