Injection molding has become a cornerstone in the automotive industry, facilitating the production of high-quality, complex parts with efficiency and precision. As the process continues to evolve, it offers remarkable benefits, including reduced production costs, shorter lead times, and the ability to create lightweight components that enhance fuel efficiency. According to Dr. Emily Zhang, a leading expert in Injection Molding Automotive technology, "The versatility of injection molding enables automakers to innovate while maintaining sustainability in their manufacturing processes."

In recent years, the automotive sector has increasingly turned to injection molding to meet the rising demand for customized parts and components that cater to diverse consumer needs. This method not only allows for intricate designs but also supports the integration of advanced materials that enhance the durability and performance of automotive products. As manufacturers strive to meet stricter environmental regulations and consumer expectations, innovation in injection molding techniques is essential for driving the future of the automotive industry.

The applications of injection molding in automotive range from exterior panels to intricate interior components, showcasing its widespread utility. As the industry embraces this technology, it opens new avenues for collaboration and transformative advancements, solidifying injection molding as a pivotal element in automotive manufacturing.

Injection molding is a manufacturing process widely utilized in the automotive industry for producing a variety of components and parts. This technique involves injecting molten plastic or other materials into a mold cavity, where it cools and solidifies to form the desired shape. It is particularly favored in automotive applications due to its efficiency, precision, and ability to create complex geometries that meet the stringent specifications required in modern vehicle design.

The definition of injection molding in the automotive industry encompasses its role in producing components such as dashboards, paneling, and under-the-hood parts. The process allows for high-volume production while maintaining the consistency and quality of each piece, essential for both functional and aesthetic aspects of vehicles. Additionally, injection molding supports the use of lightweight materials, helping to improve fuel efficiency and reduce emissions. This method also enables the integration of features like texture and color during production, reducing additional steps and enhancing the overall manufacturing process. In summary, injection molding plays a pivotal role in advancing automotive design and production efficiency.

Injection molding has revolutionized the automotive industry by offering a range of benefits that enhance manufacturing efficiency and product quality. One of the key advantages is the ability to produce complex geometries with precision. This process allows manufacturers to create intricate parts that are not only lightweight but also durable, which is essential for modern vehicles that require both performance and fuel efficiency.

Another significant benefit of injection molding is its scalability. Once the initial mold is created, manufacturers can produce large quantities of parts in a relatively short amount of time, significantly reducing production cycles. This efficiency is crucial in the fast-paced automotive market, where time-to-market can greatly impact competitiveness. Additionally, injection molding facilitates the use of a variety of materials, including thermoplastics and composites, enabling the automotive industry to tailor components to specific applications, such as interior trims, exterior panels, and under-the-hood parts.

Furthermore, injection molding contributes to sustainability efforts within the automotive sector. The process generates minimal waste, as surplus material can often be recycled and reused in future productions. This not only lowers material costs but also aligns with the industry's growing focus on environmental responsibility. By optimizing production processes and materials, injection molding supports the automotive industry's goal of creating more sustainable vehicles without compromising quality or performance.

| Application | Material Used | Benefits | Typical Parts |

|---|---|---|---|

| Interior Components | Polypropylene (PP), ABS | Great finish, cost-effective, lightweight | Dashboards, Door Panels |

| Exterior Components | Polycarbonate (PC), PBT | Durable, weather resistant | Bumpers, Grilles |

| Engine Components | Nylon (PA), Polyphenylene Sulfide (PPS) | High temperature resistance, strong | Covers, Intake Manifolds |

| Connectors | Thermoplastic Elastomer (TPE) | Flexible, excellent electrical properties | Electrical Connectors, Sensors |

Injection molding plays a crucial role in the automotive industry, offering a versatile and efficient manufacturing process for producing a variety of components. This method is particularly favored for creating intricate parts with high precision. According to a report by Mordor Intelligence, the global injection molding market in the automotive sector is expected to grow at a compound annual growth rate (CAGR) of over 5.2% from 2021 to 2026, reflecting its increasing relevance in vehicle production.

Common applications of injection molding in vehicle manufacturing include the production of interior parts, such as dashboard components, door panels, and trims, as well as exterior elements like bumpers and grilles. For instance, the ability to incorporate multiple functions into a single part significantly reduces assembly time and costs, making injection-molded parts highly desirable. Additionally, lightweight materials used in injection molding help in improving fuel efficiency, which aligns with the industry's trend towards sustainability.

According to research from the Society of Automotive Engineers, parts made through injection molding can reduce weight by around 15% compared to traditional manufacturing methods, demonstrating its effectiveness in enhancing vehicle performance and efficiency while meeting stringent regulatory standards.

Injection molding is a widely used manufacturing process in the automotive sector, allowing for the production of complex parts with high precision and efficiency. The types of materials utilized in this process greatly influence the performance, durability, and cost-effectiveness of automotive components. Commonly used materials include thermoplastics, thermosetting plastics, and composites, each offering distinct advantages suited to various applications within vehicles.

Thermoplastics are among the most favored materials in injection molding due to their flexibility and ease of processing. Materials like polypropylene (PP) and acrylonitrile butadiene styrene (ABS) are often selected for interior components, dashboards, and storage bins. Their lightweight nature contributes to overall vehicle fuel efficiency while providing sufficient impact resistance. On the other hand, thermosetting plastics, such as phenolics and epoxies, are utilized for parts requiring high heat resistance and structural integrity, making them suitable for applications like engine components where durability is critical.

Additionally, composite materials, which combine plastics with fibers such as glass or carbon, are increasingly gaining traction in the automotive industry. These composites offer remarkable strength-to-weight ratios, making them ideal for lightweight applications without compromising safety. As the automotive industry continues to evolve, the selection of appropriate materials for injection molding will play a pivotal role in enhancing performance and sustainability in vehicle production.

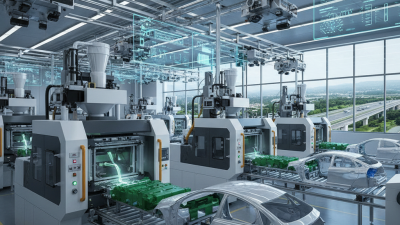

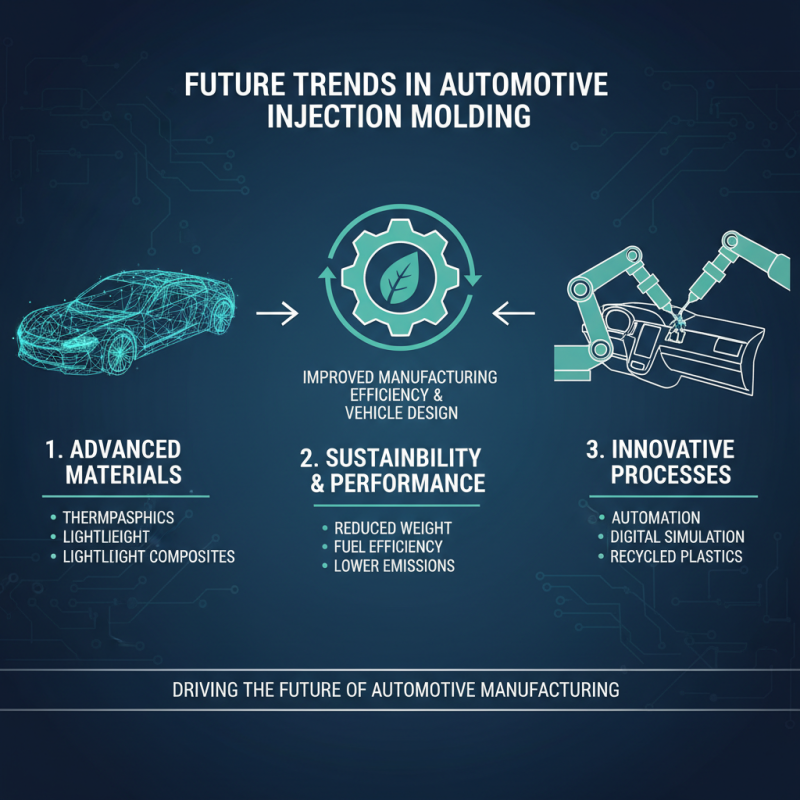

As the automotive industry continues to evolve, injection molding technology is becoming increasingly significant in improving manufacturing efficiency and enhancing vehicle design. One of the future trends in injection molding is the adoption of advanced materials such as thermoplastics and lightweight composites. These materials not only reduce the overall weight of vehicles but also improve fuel efficiency and lower emissions, aligning with the industry's push toward sustainability.

Additionally, advancements in automation and digital manufacturing are set to revolutionize injection molding processes. The integration of robotics and artificial intelligence can optimize production cycles, reduce human error, and enhance quality control. This shift toward smart manufacturing means that the automotive sector can produce intricate designs more rapidly and with greater precision, further driving innovation in vehicle aesthetics and functionality.

Tips: When considering the transition to advanced injection molding techniques, companies should invest in training their workforce to handle new technologies. Additionally, staying updated on material innovations can help manufacturers gain a competitive edge. Embracing sustainability practices not only meets regulatory demands but can also enhance brand reputation in a market increasingly focused on environmental responsibility.