In the modern landscape of manufacturing, Injection Molding Golf Cart Parts has emerged as a pivotal technique that blends efficiency with precision. As the demand for innovative golf cart components continues to rise, manufacturers are turning to advanced injection molding technologies to meet the unique needs of this niche market. This comprehensive guide delves into the latest innovations in injection molding specifically tailored for golf cart parts, highlighting how these advancements not only enhance product quality but also streamline production processes.

From material selection to design considerations, we will explore the key factors that contribute to the effectiveness of injection molding in creating durable and lightweight components. Join us as we uncover the transformative impact of these innovations, providing insights that cater to both manufacturers and consumers alike in the ever-evolving world of golf cart accessories.

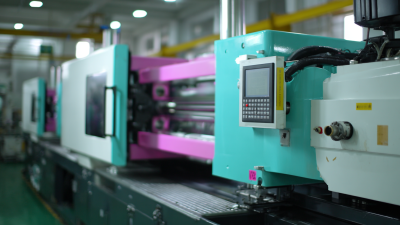

The evolution of injection molding techniques has significantly transformed the manufacturing of golf cart parts, making them more efficient and cost-effective. Traditionally, injection molding processes were limited in their scope, often resulting in longer production times and higher material waste. However, advancements in technology have led to the development of innovative methods such as multi-material injection molding and enhanced cooling systems, which not only accelerate production but also improve the durability and quality of parts.

With these modern techniques, manufacturers can now create intricate designs that meet the specific needs of golf cart users. The incorporation of lightweight materials into the molding process has resulted in parts that enhance the overall performance of golf carts, providing a better driving experience on the course. Additionally, the ability to customize parts through advanced molding techniques allows for greater personalization, catering to the preferences of golf cart enthusiasts and ensuring that they can enjoy a tailored ride that complements their gameplay style.

| Innovative Technique | Description | Advantages | Applications |

|---|---|---|---|

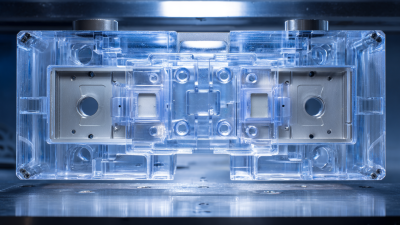

| 3D Injection Molding | A method combining 3D printing with traditional injection molding. | Faster prototyping, reduced material waste, enhanced design flexibility. | Prototype golf cart components, custom parts. |

| Gas-Assisted Injection Molding | Uses gas to hollow out parts, reducing weight. | Lighter parts, reduced cycle time, improved surface finish. | Golf cart chassis, body components. |

| Multi-material Injection Molding | Combines multiple materials into a single part. | Enhanced durability, reduced assembly time. | Golf cart interior components, ergonomic parts. |

| In-Mold Labeling | Integrates labels and graphics directly during the molding process. | Improved aesthetics, cost-effective branding. | Golf cart exteriors, dashboards. |

The golf cart industry has witnessed remarkable advancements in injection molding technologies, significantly enhancing the efficiency and quality of component manufacturing.

One key innovation is the adoption of multi-material injection molding, which allows manufacturers to combine different materials in a single process.

This not only reduces production time but also improves the durability and aesthetic appeal of golf cart parts. By integrating soft-touch materials with rigid ones, manufacturers can produce ergonomic components that enhance user comfort without compromising structural integrity.

Another notable development is the implementation of 3D printing hybrid techniques within the injection molding process.

This method enables rapid prototyping and customization of parts, allowing manufacturers to quickly adapt to market demands and specific customer requirements.

The ability to create complex geometries with intricate detailing reduces material waste and fosters sustainable practices in production.

Additionally, advancements in robotic automation have streamlined assembly lines, increasing throughput while maintaining high precision in the manufacturing of golf cart components.

Together, these innovations are revolutionizing the industry, driving both efficiency and quality in the production of golf cart parts.

Sustainability has become a pivotal concern in the manufacturing sector, and injection molding for golf cart parts is no exception. Recent reports indicate that the global market for sustainable plastics is projected to reach $25.6 billion by 2027, reflecting a significant shift towards eco-friendly materials within various industries, including automotive and recreational vehicles. This trend is particularly relevant for golf carts, as manufacturers seek to reduce their carbon footprints while meeting consumer demands for environmentally responsible products.

Innovations in injection molding technology are facilitating the production of sustainable golf cart components. For instance, the use of bioplastics derived from renewable resources is on the rise, with companies like BASF and NatureWorks leading the charge in developing materials that are both durable and biodegradable. The latest studies reveal that integrating such materials into the injection molding process can reduce greenhouse gas emissions by up to 60%, making them an attractive option for manufacturers focused on sustainability. Moreover, advancements in recycling processes have allowed for the reuse of production scrap, further minimizing waste and the environmental impact of golf cart manufacturing. As the industry continues to evolve, adopting these eco-friendly practices could be essential for companies aiming to thrive in a competitive market while contributing positively to the planet.

The durability of golf cart parts is significantly enhanced by the advent of advanced materials used in injection molding processes. Innovations such as fiberglass-reinforced composites and high-performance thermoplastics offer remarkable strength-to-weight ratios, which translate to components that can withstand rigorous outdoor conditions. These materials not only extend the lifespan of parts but also reduce maintenance costs for golf cart owners, making them a sound investment.

The durability of golf cart parts is significantly enhanced by the advent of advanced materials used in injection molding processes. Innovations such as fiberglass-reinforced composites and high-performance thermoplastics offer remarkable strength-to-weight ratios, which translate to components that can withstand rigorous outdoor conditions. These materials not only extend the lifespan of parts but also reduce maintenance costs for golf cart owners, making them a sound investment.

Tips: When selecting materials for replacement parts, consider how environmental factors like UV exposure and moisture can affect longevity. Opt for UV-stabilized materials to prevent fading and degradation over time.

Moreover, the incorporation of innovative additives can further elevate the performance of injection-molded golf cart components. For instance, anti-microbial agents can be added to seats and other interior surfaces, ensuring cleanliness and hygiene. Such enhancements not only improve user experience but also tackle issues like mold and mildew, which are common in humid environments.

Tips: Always inquire about the specific properties of materials being proposed for your golf cart parts. Understanding the benefits of different composites and additives will help you make informed decisions that align with your performance expectations.

The golf cart industry is witnessing an exciting transformation through advanced injection molding technologies, heralding a new era of efficiency and sustainability. Recent reports indicate that the global injection molding market is projected to grow from $320 billion in 2021 to over $410 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.1%. This growth is significantly driven by the automotive sector, including recreational vehicles like golf carts, which increasingly demand lightweight yet durable components.

The golf cart industry is witnessing an exciting transformation through advanced injection molding technologies, heralding a new era of efficiency and sustainability. Recent reports indicate that the global injection molding market is projected to grow from $320 billion in 2021 to over $410 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.1%. This growth is significantly driven by the automotive sector, including recreational vehicles like golf carts, which increasingly demand lightweight yet durable components.

One notable trend in the injection molding of golf cart parts is the integration of smart manufacturing techniques and advanced materials. Industry experts predict that the use of bio-based plastics and recyclables will rise, in line with environmental sustainability goals. In fact, a 2022 market analysis highlighted that around 30% of new material technologies being developed for injection molding are eco-friendly. Additionally, automation and industry 4.0 solutions, such as the Internet of Things (IoT), are streamlining production processes, reducing waste, and improving efficiency. As these trends gain traction, golf cart manufacturers are poised to benefit significantly from lower operational costs and enhanced product performance.