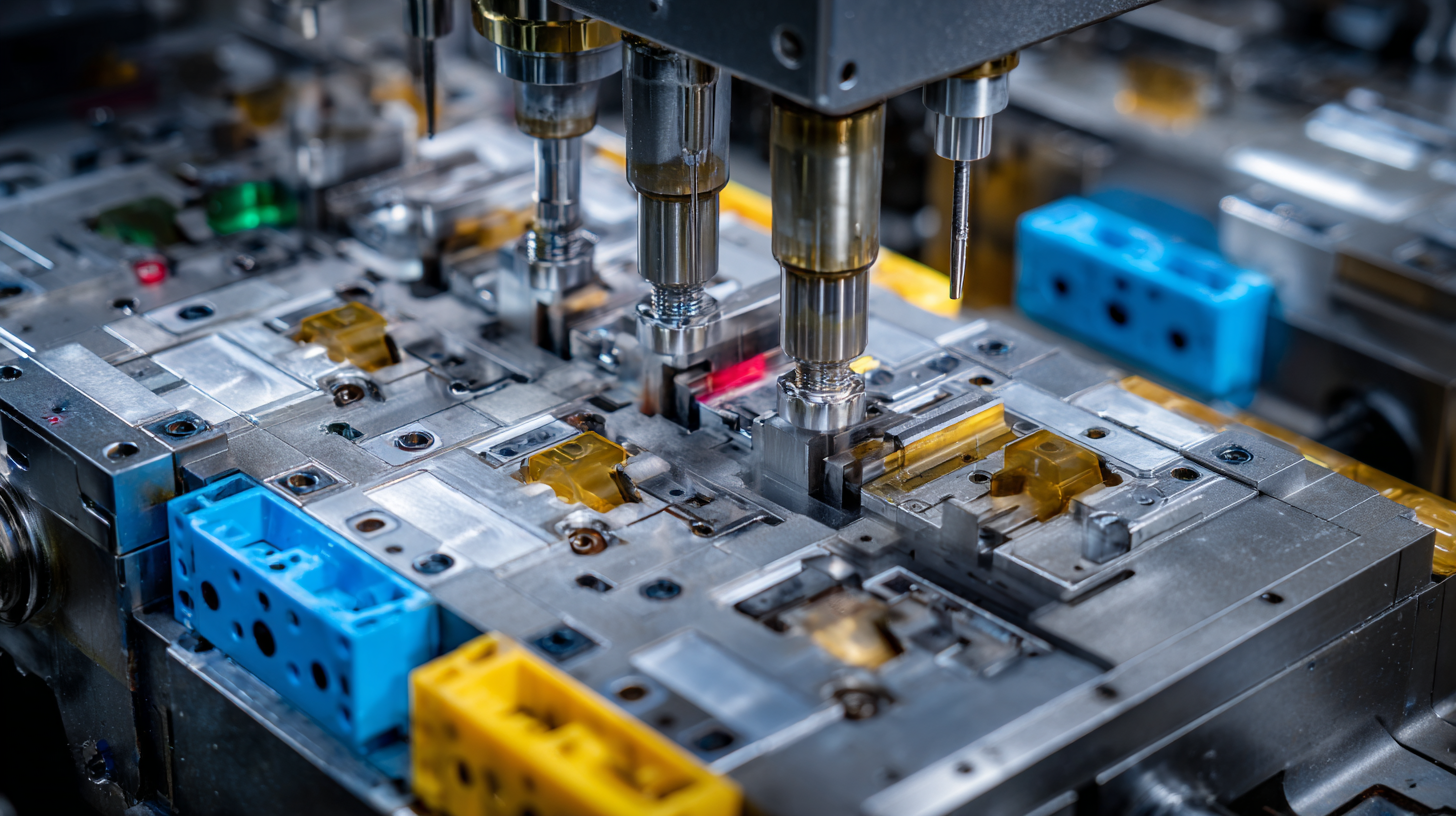

In the competitive landscape of motorcycle manufacturing, optimizing production processes is crucial for maintaining high quality and cost efficiency. One of the most significant methods employed in this sector is Plastic Injection Molding Motorcycle Parts, which delivers precision and durability for essential components. According to a report by Research and Markets, the global motorcycle parts market was valued at approximately $50 billion in 2022, with expectations to grow due to the increased demand for lightweight and high-performance materials. Furthermore, the efficiency of plastic injection molding minimizes waste and enhances production speed, making it a preferred technique among manufacturers. By focusing on optimizing parameters such as temperature control, cycle time reduction, and material selection, manufacturers can achieve superior quality in their motorcycle parts, thus elevating their market competitiveness and meeting the evolving demands of consumers.

In the competitive landscape of motorcycle manufacturing, optimizing production processes is crucial for maintaining high quality and cost efficiency. One of the most significant methods employed in this sector is Plastic Injection Molding Motorcycle Parts, which delivers precision and durability for essential components. According to a report by Research and Markets, the global motorcycle parts market was valued at approximately $50 billion in 2022, with expectations to grow due to the increased demand for lightweight and high-performance materials. Furthermore, the efficiency of plastic injection molding minimizes waste and enhances production speed, making it a preferred technique among manufacturers. By focusing on optimizing parameters such as temperature control, cycle time reduction, and material selection, manufacturers can achieve superior quality in their motorcycle parts, thus elevating their market competitiveness and meeting the evolving demands of consumers.

Optimizing plastic injection molding for high-quality motorcycle parts involves a deep understanding of several essential parameters. Among these, temperature control is paramount. According to a 2022 report by the Society of Plastics Engineers, maintaining an optimal melt temperature can enhance the flow characteristics of the plastic, which in turn affects part quality and mechanical properties. A typical recommendation is to keep the melt temperature between 200-230°C for most thermoplastics, thus ensuring consistent material flow during injection.

Another crucial parameter is injection speed. Research indicates that varying the injection speed significantly impacts the cycle time and the final product’s surface finish. A slow injection speed may lead to incomplete filling, while excessively fast speeds can cause defects such as flash and warping. Therefore, a balanced approach is essential.

**Tips**: Use temperature monitoring tools to track real-time data during the injection process. Regular calibration of injection molding machines can help maintain the quality of the motorcycle parts produced. Finally, conducting trial runs with different parameters can aid in identifying the optimal settings specific to the materials and designs being utilized.

When it comes to producing high-quality motorcycle parts, selecting the right materials is crucial. While traditional metal choices like steel and aluminum have been the mainstay in motorcycle manufacturing, the landscape is evolving. The advent of composite materials presents an exciting opportunity, offering advantages such as reduced weight and enhanced strength, which can significantly improve performance. This complexity in material selection underscores the need for manufacturers to carefully consider the specific mechanical properties required for each component, which can vary widely depending on its function within the motorcycle.

Moreover, sustainability is increasingly becoming a focal point in material selection. Some manufacturers are exploring the use of recycled materials, such as polypropylene, for bodywork, which not only reduces waste but also meets growing consumer expectations for environmentally responsible production methods. This shift towards innovative materials not only improves the overall quality of motorcycle parts but also aligns with broader industry trends aimed at reducing the environmental impact of manufacturing processes. As motorcycle manufacturers navigate these complexities, the right material choices will play a pivotal role in enhancing both the performance and sustainability of their products.

Optimizing the design of injection molds is crucial for producing high-quality motorcycle parts that meet stringent performance and aesthetic standards. Advanced mold design techniques play a pivotal role in ensuring that the molding process yields consistent results while minimizing defects. By incorporating numerical simulations into the mold design phase, engineers can predict material flow, temperature distributions, and potential weak points in the finished product. This allows for adjustments in the mold design before physical production, leading to improved efficiency and reduced waste.

Optimizing the design of injection molds is crucial for producing high-quality motorcycle parts that meet stringent performance and aesthetic standards. Advanced mold design techniques play a pivotal role in ensuring that the molding process yields consistent results while minimizing defects. By incorporating numerical simulations into the mold design phase, engineers can predict material flow, temperature distributions, and potential weak points in the finished product. This allows for adjustments in the mold design before physical production, leading to improved efficiency and reduced waste.

Tips for optimal mold design include utilizing computer-aided design (CAD) software for detailed modeling and analysis, selecting appropriate materials for the mold to withstand high temperatures and pressures, and implementing cooling channels strategically to enhance the thermal regulation during the molding process. Additionally, periodic reviews of the mold and production settings can lead to iterative improvements based on real-world data.

Incorporating innovations such as intelligent injection molding techniques can further enhance the process by providing real-time data on sensing, optimization, and control. This approach allows manufacturers to respond quickly to variances in production conditions, ensuring that each component produced performs at its best, while also maintaining high levels of quality and productivity.

Monitoring and controlling process variables during plastic injection molding is critical for manufacturing high-quality motorcycle parts. Key variables such as injection speed, temperature, and pressure must be precisely monitored to ensure optimal resin flow and part filling. According to a report by the Society of Plastic Engineers, maintaining the injection temperature within +/-1°C of the set point can result in a 20% reduction in defects and variances in part dimensions. This fine-tuned approach helps to achieve a consistent and reliable production output, which is essential for the demanding specifications of motorcycle components.

Moreover, real-time data collection and analysis play a pivotal role in enhancing process control. Implementing advanced sensors and data analytics not only helps in early fault detection but also optimizes machine settings dynamically. A study in the Journal of Manufacturing Science and Engineering indicates that facilities employing closed-loop control systems observed a 30% increase in production efficiency while reducing scrap rates by 25%. These improvements are crucial in the motorcycle industry, where weight reduction and durability are paramount, making effective monitoring and control systems integral to the success of injection molding processes.

Quality assurance methods are paramount for

ensuring consistency in the production of high-quality motorcycle parts through plastic

injection molding. Recent industry reports indicate that the global market for quality management software

is projected to reach approximately $13 billion

by 2023, with a compound annual growth rate (CAGR) of around 10%.

This growth is driven by solutions focused on non-conformance management, which helps manufacturers

identify and rectify defects promptly, thereby enhancing overall production quality.

Moreover, the deployment of cloud-based quality management systems

is gaining traction, accounting for nearly 65% of the market share.

These systems facilitate real-time data access and improved collaboration among manufacturers,

crucial for maintaining adherence to quality standards. In the motorcycle parts manufacturing sector,

implementing robust quality assurance protocols not only minimizes discrepancies but also optimizes

production efficiency, ensuring that components meet stringent safety and performance requirements.

The focus on preventive measures and effective audit management further

solidifies the foundation for consistent output in a competitive market.