Automotive injection molding has emerged as a pivotal process in the automotive industry, enabling manufacturers to create intricate and lightweight components with precision. According to a report by MarketsandMarkets, the automotive injection molding market is projected to reach USD 42.9 billion by 2025, growing at a CAGR of 4.8%. This growth is driven by increasing demand for high-performance materials and the need for cost-effective production solutions. Utilizing automotive injection molding not only enhances the aesthetic appeal of vehicle components but also contributes significantly to weight reduction, which is integral for improving fuel efficiency and reducing emissions. By mastering the intricacies of automotive injection molding, engineers and manufacturers can ensure that their next projects meet both sustainability goals and consumer expectations in a competitive landscape.

Automotive injection molding is a crucial process in the production of high-quality components for the automotive industry. Understanding the key processes involved—such as material selection, tooling, and molding conditions—is essential for optimizing production efficiency. According to a report by Research and Markets, the global automotive injection molding market is projected to reach USD 48.89 billion by 2026, highlighting the growth and importance of effective injection molding techniques in vehicle manufacturing.

Choosing the right materials is vital for ensuring the durability and functionality of automotive parts. Common materials used include polypropylene, ABS, and polycarbonate, each offering unique advantages. For instance, polypropylene is favored for its lightweight properties, while polycarbonate provides exceptional impact resistance. When selecting materials, it's essential to consider factors such as thermal characteristics and environmental resistance.

**Tips:**

1. Always conduct thorough testing on your material selection to ensure compatibility with automotive applications.

2. Invest in high-quality molds to minimize defects and enhance the overall quality of the produced parts.

3. Regularly review and update your knowledge of advancements in injection molding technology, as innovations can lead to significant process improvements and cost savings.

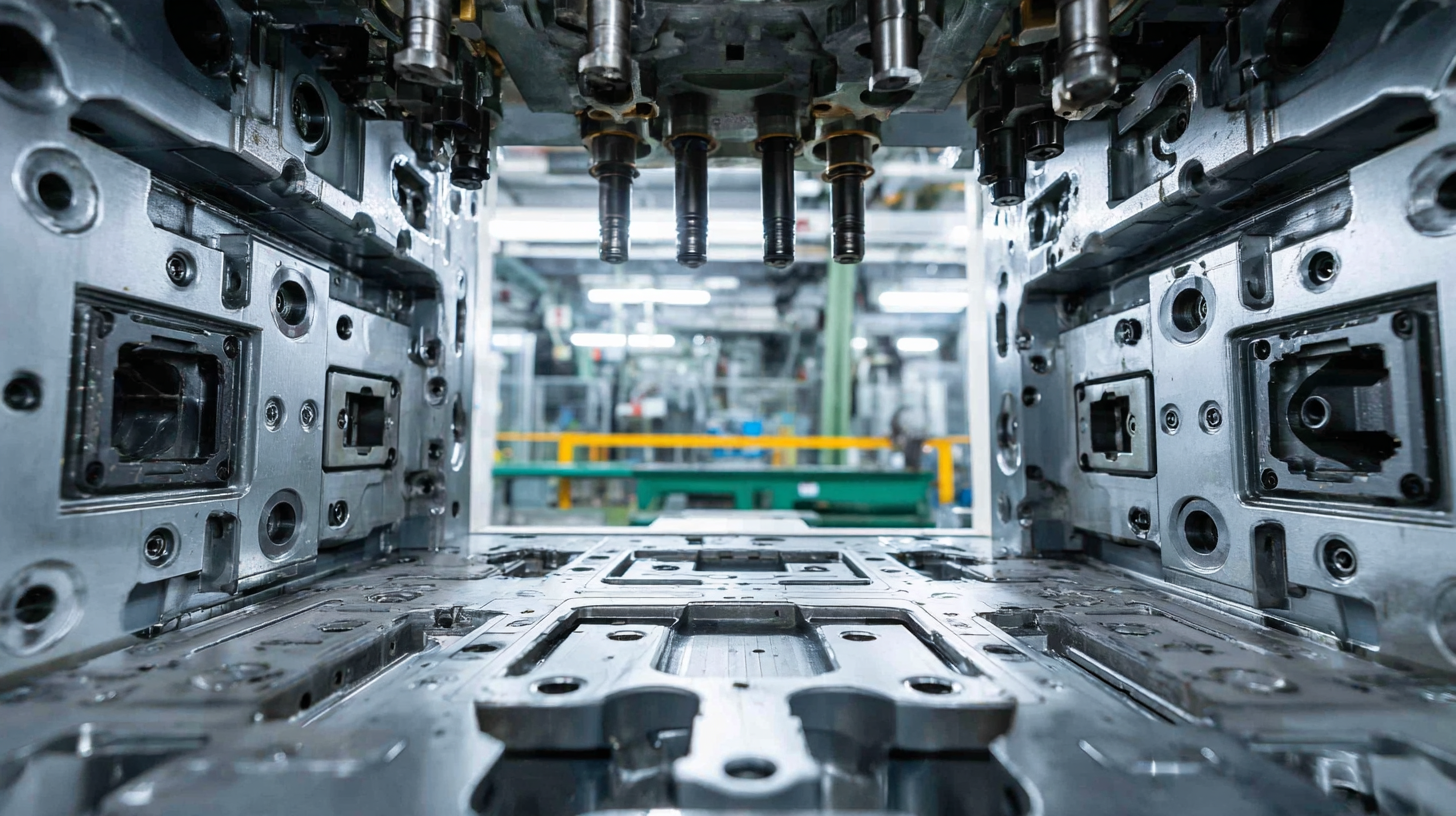

When considering automotive injection molding for your next project, selecting the right mold design is crucial for optimizing both performance and cost efficiency. According to market reports, the polypropylene sector alone is projected to grow from $855.8 billion in 2023 to nearly $893.9 billion in 2024, highlighting the increasing demand for cost-effective materials and processes in automotive applications.

In the context of electric vehicles, advanced manufacturing techniques such as laser technology have gained recognition for their role in producing high-efficiency components like lithium batteries. This reflects a broader trend towards innovation, where companies are leveraging sophisticated mold designs to enhance product performance while minimizing costs. For instance, the structural innovations in battery designs have become a focal point for improving overall efficiency, which is critical as the automotive industry continues its shift towards sustainable energy solutions.

Choosing the right mold design not only influences the quality and durability of automotive components but also plays a significant role in achieving cost efficiency. As the automotive industry evolves, integrating advanced materials and technology in mold design will be key to meeting both regulatory requirements and consumer expectations.

Automotive injection molding is a critical aspect of modern manufacturing, particularly as it pertains to the development of lightweight parts with complex geometries. An essential focus for manufacturers is optimizing cycle times and production efficiency. Industry reports project a significant growth in the Liquid Injection Molding (LIM) and Liquid Silicone Rubber (LSR) markets, with a valuation increase from $159.5 million in 2024 to approximately $283.83 million by 2032, representing a compound annual growth rate (CAGR) of 7.47%. This rising demand indicates a shift towards more efficient production methods, underscoring the need for businesses to refine their injection molding processes.

Automotive injection molding is a critical aspect of modern manufacturing, particularly as it pertains to the development of lightweight parts with complex geometries. An essential focus for manufacturers is optimizing cycle times and production efficiency. Industry reports project a significant growth in the Liquid Injection Molding (LIM) and Liquid Silicone Rubber (LSR) markets, with a valuation increase from $159.5 million in 2024 to approximately $283.83 million by 2032, representing a compound annual growth rate (CAGR) of 7.47%. This rising demand indicates a shift towards more efficient production methods, underscoring the need for businesses to refine their injection molding processes.

To achieve optimal cycle times, it is imperative to leverage advancements in machine technology and material capabilities. For instance, utilizing high-speed injection molding machines can reduce the time it takes to form parts, while automated systems can enhance precision and consistency. Moreover, the integration of smart manufacturing techniques, such as real-time monitoring and data analysis, can lead to quicker adjustments during production, further minimizing downtime. By implementing these strategies, automotive manufacturers can not only increase their production efficiency but also maintain high standards of quality in their output.

When working with automotive injection molded parts, implementing stringent quality control measures is essential for ensuring the reliability and performance of the final product. The automotive industry demands high precision, and even slight variations can lead to significant issues down the line. Therefore, establishing a robust quality control protocol—ranging from material selection to final inspections—is critical. Techniques such as materials testing, mold flow analysis, and dimensional checks should be integrated into the production process to identify potential defects early.

Moreover, the adoption of statistical process control (SPC) can help monitor and control the injection molding process by analyzing data in real-time. This enables manufacturers to detect deviations from the norm, allowing for immediate corrective actions before flawed parts are produced. Regular audits and quality checks at different stages, including pre-production, production, and post-production, ensure adherence to industry standards. By prioritizing these quality control measures, manufacturers can enhance the reliability and safety of automotive components, ultimately contributing to the overall success of their projects.

The automotive industry is undergoing a significant transformation, especially in the realm of injection molding. One of the emerging trends is the push toward sustainability. A report by the International Energy Agency (IEA) indicates that the automotive sector could reduce its carbon emissions by up to 91% by 2050 through the adoption of more sustainable manufacturing practices, including advanced injection molding techniques. This shift not only meets stricter regulatory demands but also aligns with growing consumer expectations for eco-friendly vehicles.

Innovation is another driving force in automotive injection molding. According to a recent study from MarketsandMarkets, the global automotive injection molding market is expected to reach USD 39 billion by 2026, growing at a CAGR of 7.6%. This growth is fueled by the integration of smart technologies and the development of lightweight materials, which enhance performance while minimizing environmental impact.

**Tips for Your Next Project:**

- Consider using bioplastics or recycled materials in your designs to boost sustainability metrics and appeal to eco-conscious consumers.

- Invest in advanced mold technologies that allow for faster production cycles, reducing waste and energy consumption in the process.

- Keep abreast of emerging trends in lightweight materials and automation, as these can significantly enhance the performance and profitability of your automotive components.

| Dimension | Overview | Future Trend |

|---|---|---|

| Material Use | Transition to bio-based and recycled plastics to reduce environmental impact. | Increased adoption of circular economy principles. |

| Production Efficiency | Utilization of automated and smart manufacturing processes for faster output. | Integration of AI and machine learning to optimize production lines. |

| Customization | Personalized components tailored to specific vehicle designs. | Advancements in 3D printing paired with injection molding for bespoke designs. |

| Weight Reduction | Use of lightweight materials without compromising strength. | Integration of new composites and polymers for improved performance. |

| Sustainability Practices | Efforts to minimize waste and utilize energy-efficient processes. | Monitoring and reporting of sustainability metrics for accountability. |