In today's fast-paced manufacturing landscape, the demand for quick turnaround times and cost-effective solutions has never been greater. Rapid Injection Molding emerges as a revolutionary technique that allows businesses to streamline their production processes while maintaining high-quality standards. This innovative method utilizes advanced technology to significantly reduce lead times, enabling manufacturers to respond promptly to market needs and consumer demands. As industries continue to evolve, leveraging Rapid Injection Molding can transform how products are developed and brought to market.

The significance of Rapid Injection Molding extends beyond speed; it also enhances overall cost efficiency. By minimizing material waste and optimizing resource use, companies can achieve significant savings without compromising the quality of their final products. This scalable approach allows businesses, regardless of size, to meet varying production volumes with ease, making it an invaluable strategy in competitive environments. In this article, we will explore the benefits of Rapid Injection Molding, examining how it not only accelerates production times but also contributes to cost-effective manufacturing solutions tailored to meet the needs of modern industries.

Rapid injection molding is transforming the landscape of manufacturing by significantly enhancing production speed and reducing costs. This innovative technique integrates advanced technologies that streamline the molding process, allowing for quicker turnaround times from prototyping to production. According to a report by Allied Market Research, the global market for injection molding is expected to reach $396.2 billion by 2027, propelled by the increasing demand for fast and cost-effective solutions in various industries, including automotive, aerospace, and consumer goods.

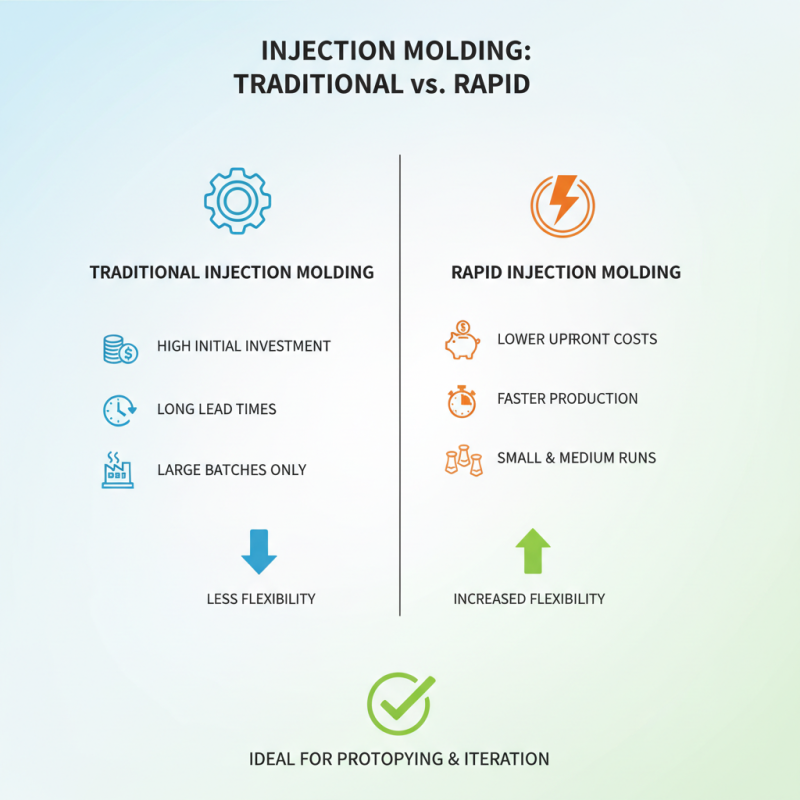

One of the key benefits of rapid injection molding is its ability to produce high-quality parts in shorter timeframes. Traditional injection molding processes can take weeks for tooling, whereas rapid injection molding can reduce this timeframe to just days, thanks to techniques such as 3D printing and CNC machining used in the creation of molds. A survey from McKinsey indicates that companies adopting rapid injection molding can cut product development cycles by up to 50%, leading to faster market entry and timely responses to consumer demands. This agility not only fosters innovation but also provides a competitive edge in an increasingly fast-paced marketplace.

Moreover, cost efficiency is greatly enhanced through rapid injection molding, as it minimizes waste and optimizes resource utilization. With traditional methods, the high initial cost of tooling can be prohibitive for small to medium-sized enterprises. However, rapid injection molding lowers the barrier to entry, allowing businesses to produce low to medium volumes of parts economically. According to the Plastic Industry Association, companies can save up to 30% in production costs by leveraging rapid injection molding technologies, making it an attractive option for manufacturers looking to optimize their operations without sacrificing quality or precision.

Rapid injection molding is rapidly becoming a vital solution for manufacturers seeking to enhance production speed while maintaining cost efficiency. One of the key advantages of this technique is its ability to significantly reduce lead times. A report from the Plastic Industry Association indicates that companies utilizing rapid injection molding can see a reduction in production times by up to 70% compared to traditional methods. This is particularly beneficial for product development cycles, allowing businesses to quickly respond to market demands and iterate on designs without the heavy financial burden associated with slower processes.

In addition to time savings, rapid injection molding offers cost efficiency that can greatly impact the bottom line. According to a study by the Society of Plastics Engineers, the use of rapid prototyping in conjunction with this molding technique can decrease tooling costs by as much as 50%. This makes it an ideal choice for low to medium production runs, where traditional molds may not be economically viable. The rapid design iterations also help in reducing waste, optimizing material use, and ensuring that investments yield higher returns.

Tips: When considering rapid injection molding, focus on materials that provide the best performance for your specific application. Additionally, collaborating closely with engineers during the design phase can uncover potential cost-saving modifications before the molding process begins. Lastly, range your production scale effectively; taking advantage of rapid injection molding’s capabilities can lead to strategic advantages in competitive markets.

This chart illustrates the production speeds of Traditional Injection Molding and Rapid Injection Molding methods. As shown, Rapid Injection Molding significantly improves production speed, leading to faster turnaround times for manufacturing.

Rapid injection molding is a revolutionary technique that streamlines the production process, offering significant advantages in speed and cost efficiency. The process begins with a thorough design phase, where engineers leverage advanced CAD software to create precise 3D models of the desired parts. This digital blueprint is crucial, as it determines the intricacies of the mold and impacts the overall production timeline. According to a report from the Society of Plastics Engineers, companies utilizing advanced design methodologies can reduce lead times by up to 60%, showcasing the effectiveness of early design investment.

Once the design is finalized, the next step involves creating the mold, commonly using 3D printing technologies. This method allows for rapid manufacturing of molds in days rather than the weeks typically required for traditional steel molds. Research indicates that companies can achieve mold production reductions from four to ten weeks down to as little as a few days with this approach.

After the mold is ready, the injection process itself is swift, with cycle times often reduced to less than 30 seconds for many applications. Given that traditional methods can take significantly longer, this efficiency not only accelerates time-to-market but also effectively lowers manufacturing costs, contributing to enhanced competitiveness in various industries.

Rapid injection molding offers significant advantages over traditional methods, particularly when it comes to cost factors. In conventional injection molding, the initial setup can be quite extensive, involving high costs for mold design and fabrication. These molds typically require longer lead times and substantial materials investment, which can deter companies from pursuing smaller production runs. Conversely, rapid injection molding utilizes advanced techniques and materials, resulting in faster mold production. This not only reduces the upfront costs but also allows for quicker iterations, making it ideal for companies seeking flexibility in their manufacturing processes.

Another cost factor to consider is the volume of production. Traditional methods often reach economies of scale, but the high initial investment can be a barrier for projects with lower volume requirements. Rapid injection molding, however, supports lower quantities without significantly increasing production costs. This approach can be particularly advantageous for startups or businesses looking to test the market with new products. Additionally, the reduced time to market afforded by rapid injection molding can lead to faster return on investment, as companies can respond swiftly to consumer demands and market trends without the burden of excess costs typically associated with traditional methods.

Rapid injection molding is a revolutionary process that significantly enhances production efficiency across various industries. In the automotive sector, for instance, manufacturers benefit from swift prototyping and mass production of components like dashboards and trims. This method not only accelerates the design cycle but also reduces lead times, enabling companies to stay competitive in a fast-paced market. By using rapid injection molding, automotive companies can quickly iterate on designs based on consumer feedback, leading to faster product launches and optimized performance.

In the consumer electronics industry, rapid injection molding facilitates the creation of intricate housings and parts that require high precision. The ability to produce durable and lightweight components on demand allows companies to respond rapidly to technological advancements and changing consumer preferences. Moreover, this method significantly lowers production costs by minimizing waste and reducing the need for extensive tooling changes. As a result, electronics manufacturers can maintain flexibility in their product offerings while ensuring high-quality standards are met.

The medical field also reaps the benefits of rapid injection molding, where the need for reliable and timely production of devices is critical. Customizable and precise manufacturing allows for quick adaptation to evolving healthcare standards and patient requirements. This technology supports the production of items like surgical instruments and diagnostic equipment, where precision and efficiency are paramount. By leveraging rapid injection molding, medical device companies can improve their R&D capabilities and expedite the delivery of essential products to the market.

| Industry | Application | Key Benefits | Production Speed (units/hour) | Cost Reduction (%) |

|---|---|---|---|---|

| Automotive | Interior Components | Reduced lead time, lightweight parts | 300 | 30 |

| Consumer Electronics | Casing and Housings | Design flexibility, quick iterations | 250 | 25 |

| Medical Devices | Disposable Instruments | High precision, sterile production | 200 | 20 |

| Aerospace | Structural Components | Weight savings, enhanced aerodynamics | 150 | 15 |

| Packaging | Custom Molds for Containers | Reduced waste, lower material costs | 350 | 35 |