When embarking on a new project, selecting the right Injection Molding process is crucial to ensuring both efficiency and product quality. Injection Molding is a widely used manufacturing technique that allows for the mass production of complex plastic components with precision and repeatability. However, with various types of Injection Molding methods available, such as conventional, gas-assisted, and multi-material molding, making an informed choice can be daunting. Understanding the specific requirements of your project, including material selection, part geometry, and production volume, will be essential in determining the most suitable process. This guide aims to provide you with a clear framework for evaluating your options, highlighting key factors to consider in order to optimize your project outcomes while minimizing costs and production time. Whether you are a seasoned engineer or a newcomer to the field, this insight into the Injection Molding selection process will empower you to make educated decisions for your next endeavor.

When selecting the right injection molding process for a project, understanding the specific project requirements and material specifications is crucial.

The first step is to clearly define the functional needs of the final product, including dimensions, tolerances, and end-use conditions.

Considerations such as mechanical strength, flexibility, and thermal resistance can significantly influence material choice and molding process selection.

For instance, products intended for high-stress environments may require engineering plastics or specialized compounds that can withstand extreme temperatures or pressures.

Additionally, it's essential to evaluate the material specifications for compatibility with the injection molding process.

Factors such as melt flow index, viscosity, and cooling characteristics directly impact the efficiency of production and the quality of the final part.

If a particular material is more viscous, it may necessitate adjustments in mold design or processing parameters like temperature and pressure to ensure optimal flow and part integrity.

By closely aligning project requirements with material specifications, manufacturers can streamline the injection molding process and enhance overall project outcomes.

When evaluating different injection molding techniques for your next project, the intricacies of each method become critical in determining the best fit for your needs. Traditional injection molding remains a popular choice due to its efficiency and ability to produce high-volume components. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $371.7 billion by 2025, emphasizing its vital role in various industries, including automotive, consumer goods, and healthcare.

However, alternative techniques such as gas-assisted and thin-wall injection molding are gaining traction. Gas-assisted injection molding is particularly advantageous in reducing the weight of parts while maintaining structural integrity. A study published in the Journal of Manufacturing Science and Engineering found that products made using this technique can be up to 30% lighter than those produced by traditional methods. Furthermore, thin-wall injection molding allows for faster cycle times and reduced material costs, making it ideal for applications where reducing production time is critical. Choosing the right technique involves weighing these benefits against project-specific requirements, including part complexity, material compatibility, and production volume.

When selecting the right injection molding process for your next project, understanding the cost and time efficiency of various methods is crucial. Traditional injection molding offers high-speed production and low per-unit costs, making it ideal for large batch sizes. However, the initial setup costs can be significant, as these methods often require expensive molds and long lead times. The investment may not be justifiable for smaller runs or prototypes.

On the other hand, alternatives such as 3D printing and provide flexibility and faster turnaround times. 3D printing, for instance, eliminates the need for costly molds and allows for rapid prototyping, enabling designers to iterate quickly. While the cost per unit can be higher for small quantities, the reduced time to market can offset these expenses. Low-volume injection molding can also be a viable compromise, providing quick production without the high initial costs associated with traditional methods. Each process should be evaluated based on specific project needs, balancing budget constraints with the urgency of project deadlines.

When selecting the right injection molding process for your next project, production volume and scalability options are critical factors to consider. High-volume production typically necessitates processes that can maintain consistent quality and reduce per-unit costs. Data shows that advanced manufacturing technologies, such as 3D printing and additive manufacturing, have been assessed for their scalability and efficiency in producing complex geometries. A mathematical model highlighting fundamental scaling relationships indicates potential optimizations in both additive manufacturing and traditional injection molding processes, allowing manufacturers to respond dynamically to changes in demand.

Furthermore, a technoeconomic assessment of nanocellulose production suggests that moderate refining combined with enhanced technologies presents viable scalability. This approach can similarly be applied to injection molding, where optimizing the refining and molding processes can lead to significant energy savings and financial profitability. As industries evolve towards greener practices, evaluating the integration of renewable resources and innovative techniques in injection molding not only enhances environmental sustainability but also guarantees scalability, ensuring that projects can adapt to market needs effectively.

| Injection Molding Process | Ideal Production Volume | Scalability Options | Typical Lead Time |

|---|---|---|---|

| Standard Injection Molding | 10,000 - 1,000,000 units | High scalability; multiple molds | 4-8 weeks |

| Prototype Injection Molding | 1 - 10,000 units | Limited scalability; suitable for testing | 2-4 weeks |

| Medical Injection Molding | 10,000 - 500,000 units | Moderate scalability; regulatory compliance | 6-12 weeks |

| Short-Run Injection Molding | 1 - 50,000 units | Flexible scalability; quick changes | 1-3 weeks |

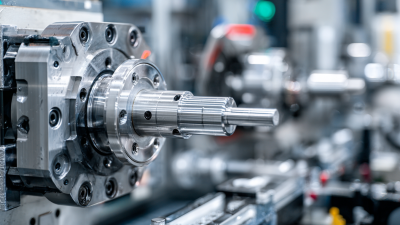

When embarking on a new injection molding project, selecting the right equipment and technology is crucial to meeting your specific production needs. Factors to consider include the type of materials you plan to use, the complexity of the parts you wish to create, and the desired production volume. For instance, if you are working with thermoplastics and require high precision, investing in advanced injection molding machines with state-of-the-art controls may be advantageous. Evaluating the necessary features, such as shot size, clamping force, and cycle time, will help in choosing the optimal machine for your project.

In addition to the machinery, it's essential to consider the technology that complements your injection molding process. This could involve automated systems for efficiency, mold design software for precision, and monitoring tools that ensure quality control throughout production. Understanding the latest trends in injection molding technology can also inform your decision-making process, allowing for innovations that enhance product quality and reduce costs. By aligning your equipment and technology choices with your project’s specific demands, you ensure a smoother, more efficient production process that meets industry standards.