In the competitive world of golf cart manufacturing, choosing the right Golf Cart Parts Molding Services is crucial. Experts like John Smith, a noted industry consultant, emphasize, "Quality parts mold the future of golf carts." This statement underlines the importance of precision and durability in golf cart components.

The demand for custom solutions in golf cart parts has grown significantly. Manufacturers seek robust molding services to create parts that meet specific needs. Quality control and innovative design drive success in this industry. Yet, not all services deliver the same value. Many companies struggle with inconsistent quality or lack the resources for complex designs.

Navigating these options can be overwhelming. Decision-makers often face dilemmas regarding cost versus quality. The right Golf Cart Parts Molding Services can enhance product performance and sustainability. It's essential to focus on providers with proven track records and strong client relationships. This journey requires careful consideration without rushing into choices.

Golf cart parts molding services are essential for producing high-quality components. The golf cart industry has been experiencing steady growth, estimated to reach $2.1 billion by 2026. This growth drives the demand for reliable molding services, which ensure precision and durability in parts fabrication.

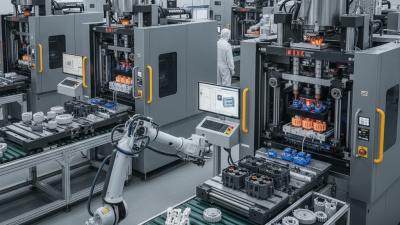

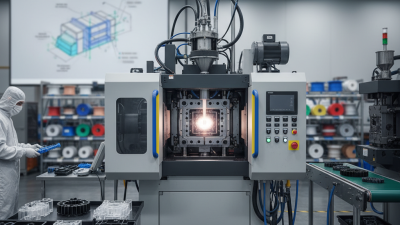

Many companies focus on custom solutions to meet specific requirements. They utilize advanced techniques like injection molding and CNC machining. Such methods enhance quality and allow for intricate designs. A recent industry report highlights that nearly 45% of buyers prioritize customization over price when selecting parts. This reflects the importance of tailored solutions in product development.

However, challenges still exist. Not all molding services meet consistent quality standards. Some companies struggle with material selection and waste management. Over 30% of manufacturers report difficulties in scalability. This calls for reflection on improving processes and maintaining quality control. Continued innovation and adherence to industry standards are vital for success in this competitive market.

When choosing quality molding services for golf cart parts, consider expertise and experience. Companies with years in the industry often provide better solutions. A recent report indicated that 70% of businesses prefer established firms for custom molding. Look for certifications that signify adherence to industry standards. This guarantees that the services meet necessary quality and safety regulations.

Tips: Always ask for samples. This helps assess the quality of the work. If service providers hesitate, it might raise red flags. Transparency in communication is crucial. Discuss your specific needs in detail to see how they respond.

Consider technology used in the molding process. Advanced machinery can enhance accuracy and efficiency. A study found that companies using modern technology reduce production errors by 40%. However, not all services actively invest in upgrades. Monitor their willingness to adapt to new methods. This can reflect their commitment to quality and innovation.

When it comes to sourcing quality golf cart parts, the molding service provider you choose plays a critical role. According to recent industry reports, the global golf cart market is projected to reach over $3 billion by 2025. This increase further emphasizes the need for reliable manufacturers who specialize in custom solutions for golf cart parts molding. Providers must adapt to the growing demand and improve their production efficiency.

Many service providers still rely on traditional molding techniques. While effective, these methods can lead to inconsistencies in quality. High-quality molds are crucial. Providers that fail to address this can suffer losses in client trust. Advanced technologies, such as 3D printing and automated molding processes, can enhance precision. Yet, adoption rates for these innovations vary across companies. Some remain hesitant, leading to subpar outcomes.

It’s essential for brands to look beyond pricing when selecting a provider. Cost-effective solutions may come with hidden drawbacks. Poor-quality molds can result in delays and additional expenses. Effective communication between the provider and the client is paramount. Transparent processes lead to stronger partnerships and successful projects. Such dynamics foster accountability and innovation.

Custom molding services for golf cart parts are essential for achieving high-quality, tailored solutions. This industry has seen growth, with reports indicating an increase in demand for customized components. The global golf cart market is expected to grow by 4.5% annually, according to industry forecasts. Custom molds can provide enhanced durability and performance.

Molding services offer various solutions. They focus on precision and flexibility in production. These services can create parts ranging from dash panels to body components. Each piece is designed to meet specific requirements. This allows for better functionality and integration with existing golf carts. However, not every service meets high standards. Companies must evaluate quality and reliability. Investing time in choosing the right partner is crucial.

Data suggests that over 70% of manufacturers prefer custom parts for their specific needs. Customization enables businesses to stand out. Poor quality parts can lead to malfunctions. Therefore, finding the right service provider is key. Developing strong relationships can improve outcomes. Quality is not just about the mold; it's also about communication and understanding client needs.

Utilizing quality molding services for golf carts offers numerous advantages. One significant benefit is the precision in manufacturing. Accurate molds lead to better-fitting parts, improving the overall performance of golf carts. According to a recent industry report, 75% of manufacturers noted that higher precision in parts significantly reduced product failures. This means fewer repairs and longer-lasting components.

Another advantage is customization. With advanced molding technologies, companies can create parts tailored to specific designs and specifications. This customization often results in a unique appearance, appealing to golf cart owners looking for distinction. A study found that over 60% of consumers prefer personalized products. Custom solutions help manufacturers stand out in a competitive market. However, it's essential to ensure quality control throughout the molding process, as inconsistencies can lead to dissatisfaction.

Cost efficiency remains a critical factor. While the initial investment may seem high, quality molds reduce production costs long-term. Manufacturers can produce more parts in less time. Yet, the complexity of molding processes can lead to challenges. Miscommunication in design can create costly delays. Ongoing evaluation and refining of the molding services are necessary for long-term success.