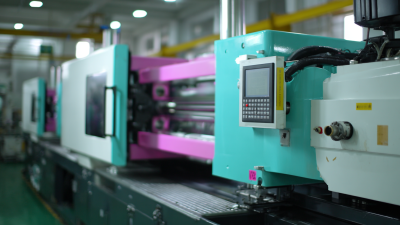

In the world of manufacturing, quality plays a vital role. Injection molding companies stand at the forefront of this process. They produce various plastic products used in everyday life. From automotive parts to consumer goods, their impact is significant.

Finding reliable injection molding companies is essential for businesses. Companies must evaluate capabilities, technology, and quality control. Not all providers meet the same standards, and this inconsistency can lead to challenges in production. Some firms may promise quality but fall short during execution.

Yet, within this competitive landscape, a select group consistently excels. These top companies not only deliver superior products but also prioritize customer satisfaction. Their commitment to quality solutions sets them apart. However, even the best face obstacles. They must continually adapt to new technologies and market demands to remain relevant. This ongoing challenge shapes the industry landscape.

Injection molding plays a pivotal role in modern manufacturing. This process allows for the efficient production of complex parts. According to a recent industry report, injection molding accounts for approximately 30% of global plastic production. It provides high precision, scalability, and a variety of material options.

However, not every injection molding process guarantees quality. Variations in temperature and pressure can lead to defects. A study shows that 60% of manufacturers struggle with quality consistency. This demonstrates the need for refined techniques and standards. It's crucial to identify potential areas for improvement.

The importance of effective design cannot be overstated. Poor design can lead to costly production errors. It can also increase waste and reduce profitability. Many companies overlook the significance of prototype testing, which is essential for refining designs. Emphasizing quality solutions in injection molding can transform how industries manufacture their products.

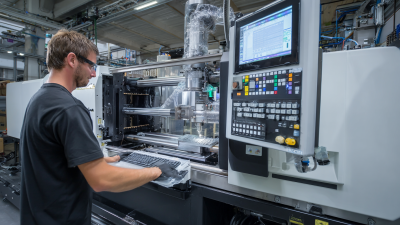

Selecting top injection molding companies involves careful consideration. Quality solutions do not just happen. Companies must be evaluated based on specific criteria. Experience in the industry is crucial. Companies that have operated for over 10 years often have better capabilities. They typically possess refined processes and skilled labor. According to the Plastic Industry Association, over 80% of successful companies have established robust operational standards.

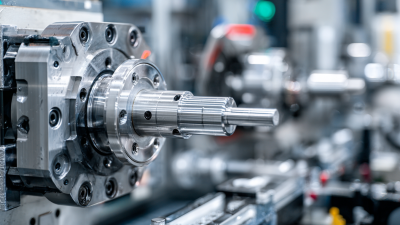

Another important factor is technological capability. Advanced machinery is essential for producing high-quality parts. Companies that invest in state-of-the-art technology often achieve more efficient production cycles. The market shows that companies employing automation save up to 25% on overhead costs. This type of investment reflects a commitment to innovation.

Finally, customer service cannot be overlooked. A responsive team fosters better collaboration. Companies that prioritize communication often resolve issues faster. Surveys indicate that 74% of clients consider support crucial in their selection process. It is important for firms to understand their clients' needs. Failing to do so may lead to misunderstandings and poorer outcomes. A holistic approach to these criteria can significantly impact the quality of injection molding solutions delivered.

The injection molding industry is a backbone for many sectors, including automotive and consumer goods. Companies in this field specialize in various applications. They often focus on precision and quality, delivering intricate designs that meet strict regulatory standards. A 2021 report indicated that more than 80% of manufacturers prioritize quality control in production. This commitment ensures that parts not only meet specifications but also perform reliably under pressure.

Tips: Always verify the quality certifications of a company before engagement. It’s essential to understand their niche expertise. Different companies excel in particular types of materials or techniques. Collaborating with a specialized firm often leads to better results.

Many companies innovate by utilizing sustainable materials and processes. A recent survey showed that around 40% of companies are adopting eco-friendly practices. This shift is crucial as consumers demand greener solutions. However, some firms still struggle with transitioning to better practices due to cost or resource constraints. It’s important for all organizations to reflect on their environmental impact continuously.

Tips: Assess how a company’s practices align with your own values. This consideration can influence brand reputation and customer trust. Investing in the right partner can optimize both production quality and sustainability efforts.

| Company Location | Year Established | Specialties | Certifications | Annual Revenue (Approx.) |

|---|---|---|---|---|

| USA | 1990 | Automotive Parts, Consumer Products | ISO 9001, IATF 16949 | $50 million |

| Germany | 1985 | Medical Devices, Precision Components | ISO 13485, CE Mark | $100 million |

| China | 2000 | Consumer Electronics, Household Goods | ISO 9001 | $30 million |

| Japan | 1975 | Automotive, Aerospace Components | AS9100, ISO 9001 | $200 million |

| Canada | 1999 | Packaging, Industrial Parts | ISO 9001, FDA Approved | $25 million |

| France | 1988 | Consumer Goods, Appliances | ISO 9001, BRC Certified | $60 million |

| Italy | 1995 | Electrical Components, HVAC | ISO 9001, UL Listed | $90 million |

| Sweden | 1982 | Medical Supplies, Technical Plastics | ISO 13485 | $75 million |

| South Korea | 2010 | Automotive, Electronics | ISO 9001 | $20 million |

| Netherlands | 1980 | Packaging, Consumer Products | ISO 9001, FSC Certified | $40 million |

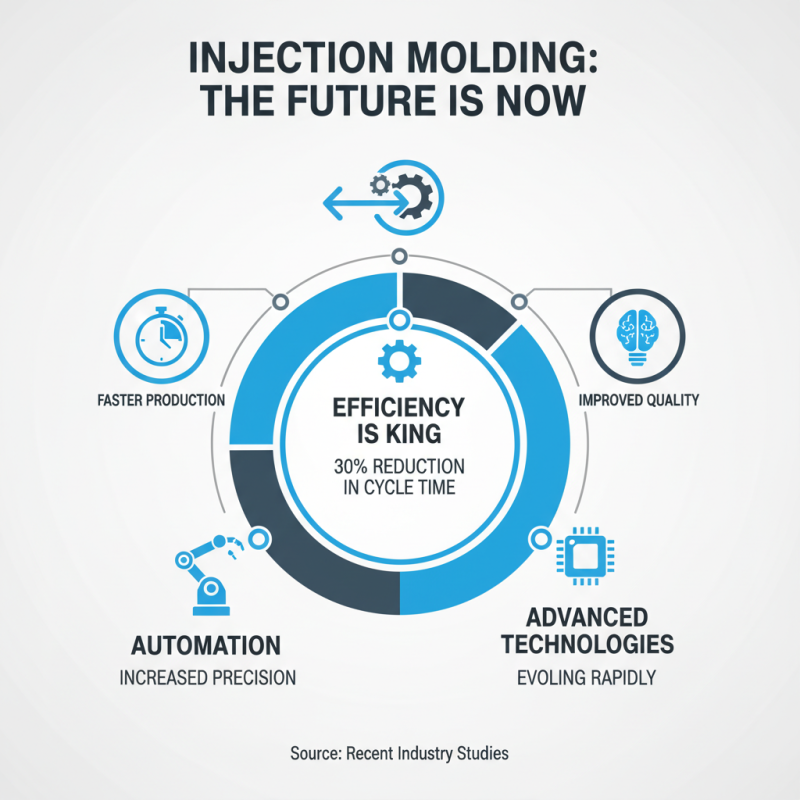

Injection molding is evolving rapidly. Innovations are reshaping how parts are made. Efficiency is king. Advanced technologies are becoming standard. For instance, automation in injection molding increases precision and reduces cycle times. Recent studies show that automated systems can cut production time by 30%. That's significant for manufacturing.

3D printing integration is another game changer. This technology allows for prototyping and lower production costs. According to industry reports, about 45% of manufacturers are adopting this method. This shift enhances creativity and reduces waste. Using simulation software is also vital. It helps predict potential issues before they arise.

Consider these tips: Ensure to stay updated with the latest technology trends. Evaluate how innovations can fit into your production line. Also, don’t overlook training for your team. Skilled operators are essential for maximizing efficiency. Always be open to reflecting on your processes. Improvement is a continuous journey.

Choosing the right injection molding company can be daunting. Customer feedback plays a vital role in this decision. Many clients share their experiences online. They're looking for quality, responsiveness, and reliability.

Some companies reported delays that affected their production timelines. Clients felt frustrated by the lack of communication during these periods. However, the feedback also highlighted those companies that improved transparency over time. This type of commitment builds trust, which is essential in this industry.

When selecting a provider, consider these tips: Ask for samples of previous work. This provides insight into their capabilities and quality. Look for reviews and testimonials. They often reflect the true performance and customer service of a company. Don't hesitate to reach out and ask questions. Direct communication can unveil important information.